Robotic Programming

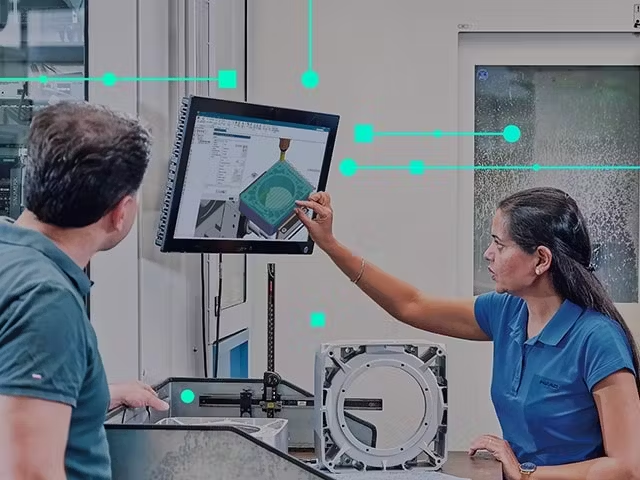

Automate your part manufacturing with advanced robotic technology to extend machining capabilities, minimize cycle times, and enhance overall part quality.How Robotics Can Modernize Your Production

Robotic technology brings a new level of automation and flexibility to manufacturing, significantly enhancing efficiency,

precision, and productivity on the shop floor.

Explore the powerful capabilities of advanced robotic automation:

Expand Capabilities with Robotic Machining

Leverage robotic machining to handle large parts and extend your machining work envelope. Robots enable the automation of tasks traditionally performed manually, improving efficiency and consistency.

With NX CAM, you can easily program and simulate robots to execute precise multi-axis machining operations such as:

- Trimming

- De-burring

- Grinding

- Polishing

Advanced robotics help you reduce production costs, enhance machining accuracy, and boost overall productivity.

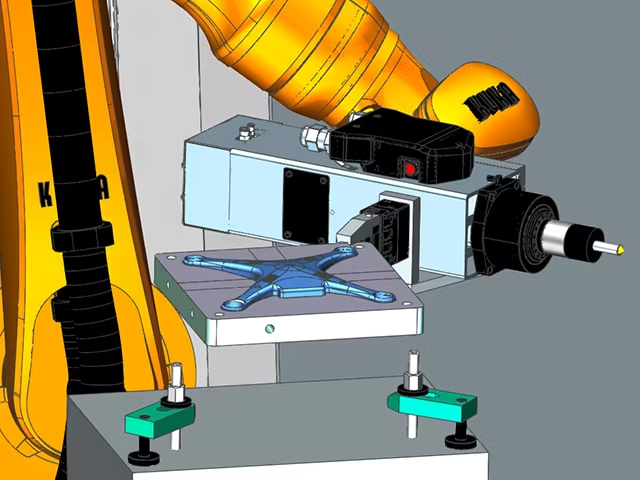

Program Robots for Pick-and-Place Operations

Enhance automation in your part manufacturing process by deploying robots for pick-and-place tasks such as machine tending and tool loading.

By automating these repetitive operations, you can enable extended unattended machining, significantly increasing productivity and maximizing production capacity.

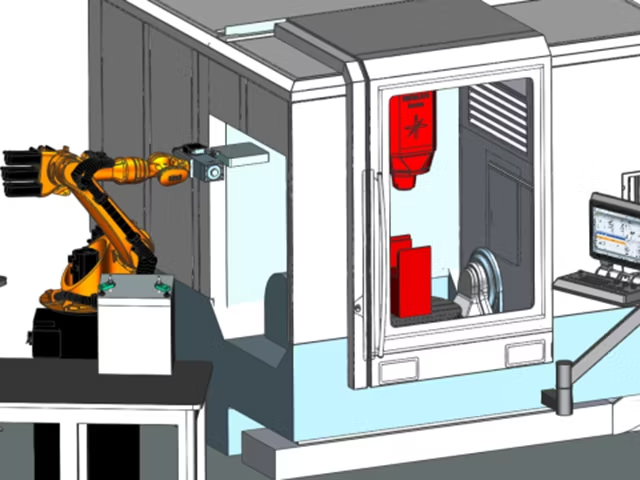

Automate Complete Production Workcells Using Robots

Boost shop floor productivity with fully automated workcells that integrate advanced robotics and CNC technology. Modernize your production processes to reduce costs, minimize lead times, and improve overall efficiency.

With NX, you can program complete automated workcells to perform a full range of operations, including:

- Robotic machine tending

- CNC machining

- Robotic machining

Webinar

Digital Machine Shop: Tomorrow’s CAM Software for Multi-Axis Machining and Robotics

Join this webinar to discover how Siemens NX empowers manufacturers to accelerate part production by harnessing the technologies of tomorrow — today.

Explore NX X Manufacturing Products

Discover our comprehensive suite of cloud-based solutions tailored to meet your unique part manufacturing needs.

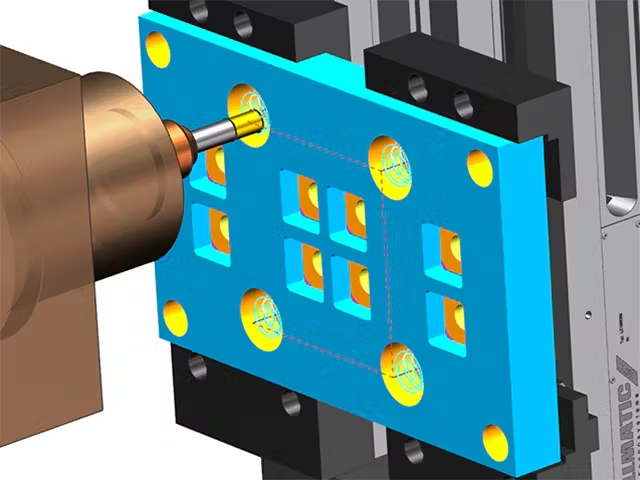

NX X Manufacturing Standard

Automate prismatic part programming with integrated CAD/CAM technology, featuring 2.5-axis milling, hole making, turning, and on-machine probing capabilities—all seamlessly connected to industry-leading CAD tools and powered by cloud technologies.

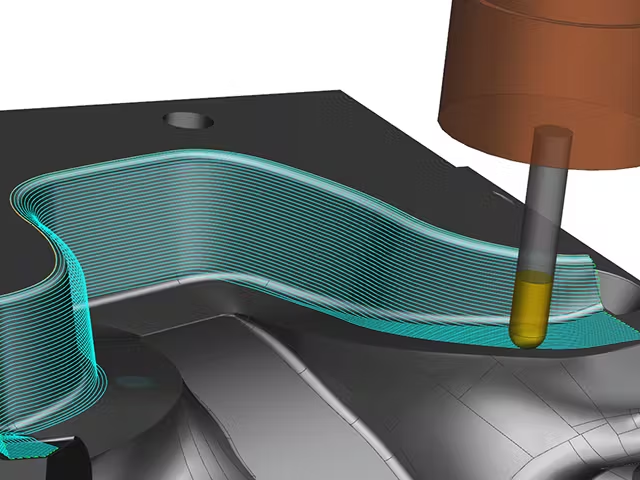

NX X Manufacturing Advanced

Use advanced 3- and 2.5-axis milling, turning, on-machine probing capabilities among other advanced functionalities. Leverage integrated CAD/CAM tools streamline the preparation & programming of the most demanding freeform parts.

NX X Manufacturing Premium

Utilize 5-axis milling, rotary machining, advanced 3- and 2.5-axis milling, turning, and on-machine probing capabilities, along with other high-end functionalities. Optimize complex part machining with powerful multi-axis machining strategies.

NX X Manufacturing Value Based Licensing

NX X Manufacturing add-ons are available exclusively through our innovative Value-Based Licensing model, offering a flexible and cost-effective way to extend your capabilities. Enhance your NX X Manufacturing solution with a wide range of powerful add-ons.Siemens Teamcenter Share

Optimize your entire production process with Teamcenter Share — a cloud-based collaboration solution that seamlessly integrates with NX CAM software. Securely communicate and share information with internal teams and external partners through a connected cloud environment.

Unify design, manufacturing, and shop floor teams to achieve more flexible, efficient, and transparent production workflows.