NX for manufacturing

NX X Manufacturing

Premium

Simplify programming of complex parts with NX X Manufacturing Premium, building upon the Advanced product, with multi-axis machining powered by cloud technologies.

₹1,046,831.19

INR

per quantity / per year

Only ₹87,235.93 per month

You’re viewing products and pricing for India

Change country

Why NX X Manufacturing Premium?

NX X Manufacturing Premium is Siemens’ most comprehensive manufacturing solution, building upon the Advanced package. It combines simultaneous 5-axis milling and rotary machining with 3-axis and 2.5-axis milling, turning, and on-machine probing capabilities, offering a complete toolset for modern CNC manufacturing.

The 5-axis milling functionality provides advanced toolpath strategies for precise control and safe machining of complex components in a single setup. High-speed adaptive roughing significantly reduces machining time, while guiding curve finishing ensures superior surface quality. Techniques like swarf cutting and tube milling optimize tool life and enable efficient machining of narrow or hollow features. Real-time visualization of toolpaths and rotary positions enhances accuracy and control.

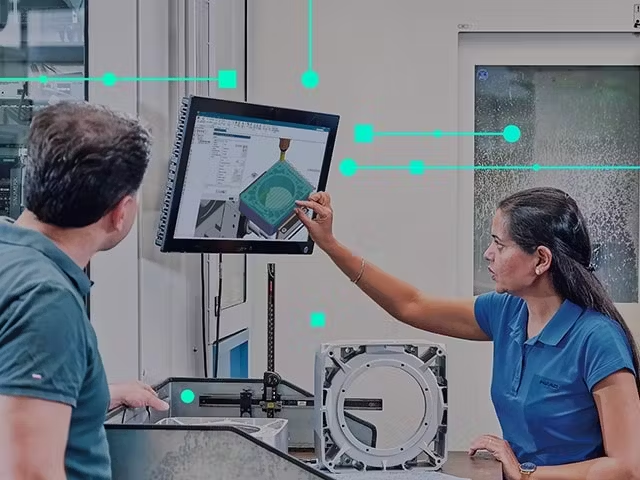

The data management system enables CAM data handling and cloud-based file management, including revision control and check-in/check-out functionality. Integrated discussion threads and task assignments promote seamless collaboration between design and manufacturing teams.

With rotary machining, users can efficiently execute 4-axis milling operations, optimizing tool contact and automating rest milling to eliminate uncut material. 3-axis milling introduces 3D Adaptive Roughing to shorten cycle times and ensure precision in multi-stage roughing, while smooth finishing techniques deliver exceptional surface finishes.

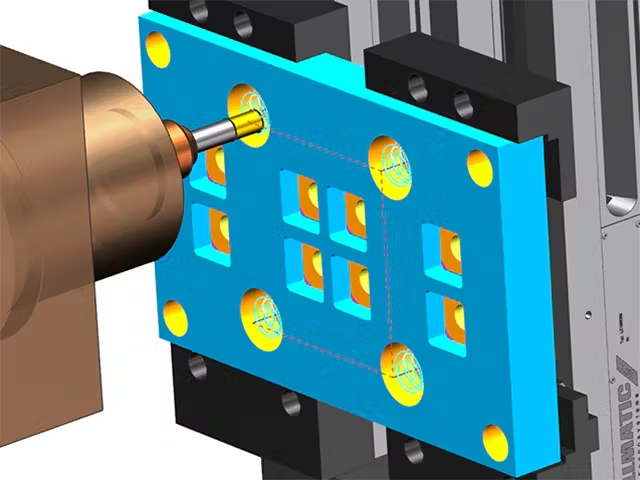

In 2.5-axis milling, volume-based and feature-based machining allow faster programming of prismatic parts, cutting machining time by up to 60%. Multi-part programming further boosts productivity. Turning operations are equally robust, supporting cylindrical part machining on single or dual spindles, with advanced roughing, finishing, grooving, threading, and hole-making operations for both outer and inner diameters.

The on-machine probing feature enables users to generate and simulate probing paths, ensuring process accuracy through real-time variation detection. Integrated postprocessing and digital twin simulation of parts, probes, and tools guarantee precise NC code output and error-free production.

Finally, the inclusion of integrated CAD tools provides superior modeling, editing, and assembly capabilities. With support for multiple standard data formats (IGES, DXF, STEP, STL, JT), NX CAM accelerates CNC programming and improves design-to-manufacture efficiency.

Manufacturing performance metrics are based on internal test machining and comparative studies, reinforcing NX X Manufacturing Premium as a powerful, end-to-end solution for high-performance manufacturing.

Benefits of NX X Manufacturing:

- Tailored precision: Program with advanced CAD/CAM tools designed to meet your specific manufacturing requirements.

- Lower costs, faster setup: Minimize upfront expenses and accelerate deployment through cloud-based technology.

- Boost productivity: Leverage industry-leading CNC programming to enhance efficiency and output.

- Collaborate seamlessly: Improve communication and coordination across teams with cloud-enabled collaboration tools.

- Scale with flexibility: Extend capabilities and optimize usage through Value-Based Licensing.

Customizable solution

Enhance and tailor your manufacturing capabilities with NX X Manufacturing Value-Based Licensing, enabling you to configure and expand your solution with:- Advanced modeling tools for precise design and engineering

- Specialized machining capabilities to meet unique production requirements

- G-code–driven simulation for accurate verification of machining processes

- Modern postprocessing solutions for efficient and reliable output

NX X Manufacturing Premium capabilities

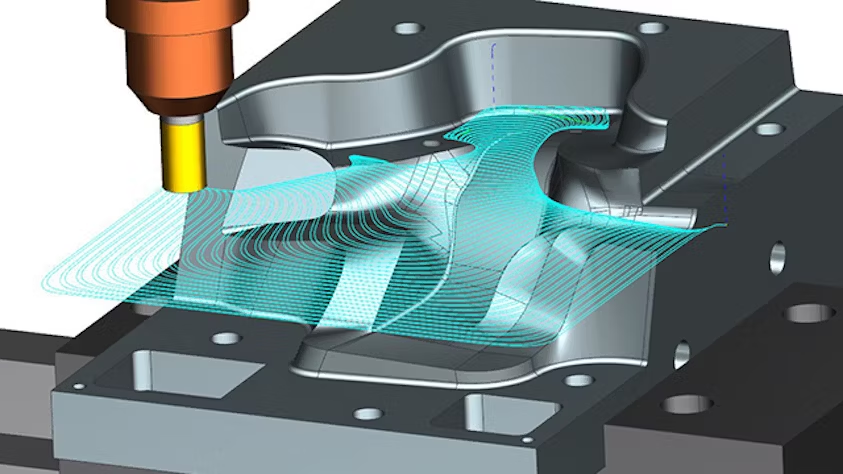

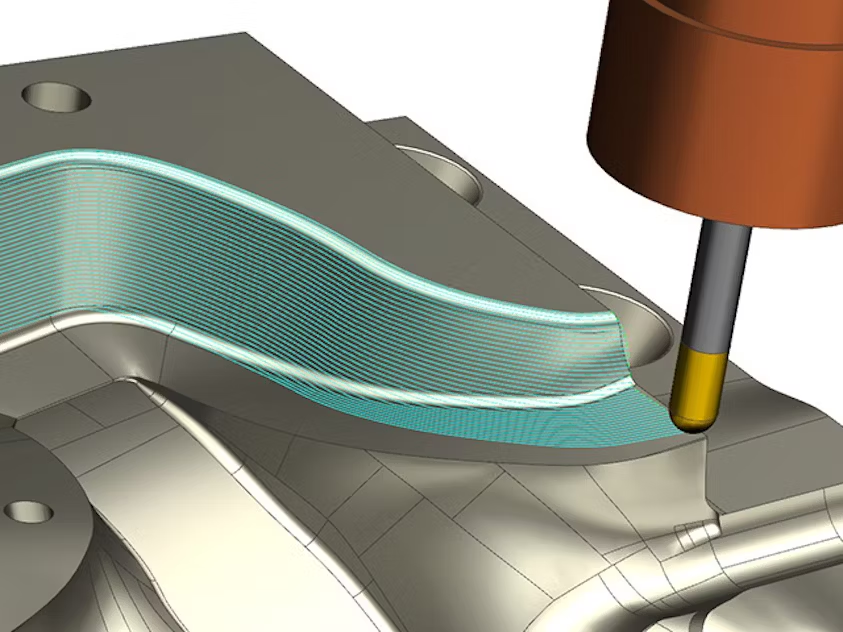

Advanced 5-Axis Simultaneous Milling

NX simplifies the programming of complex, multi-sided parts through its advanced 5-axis simultaneous milling capabilities. With minimal user input, the software automatically generates optimized toolpaths for intricate geometries, enabling machining in a single setup and significantly reducing the need for part repositioning. The intelligent tool control features — including automatic tool orientation and dynamic lead/lag angle adjustments — ensure precise engagement between the tool and the part surface. This leads to smoother toolpaths, superior surface finishes, and high-quality results even on challenging contours and undercuts. Additionally, the integrated collision avoidance system continuously monitors and adjusts toolpaths in real time, ensuring safe and efficient machining operations while maximizing material removal and tool life.

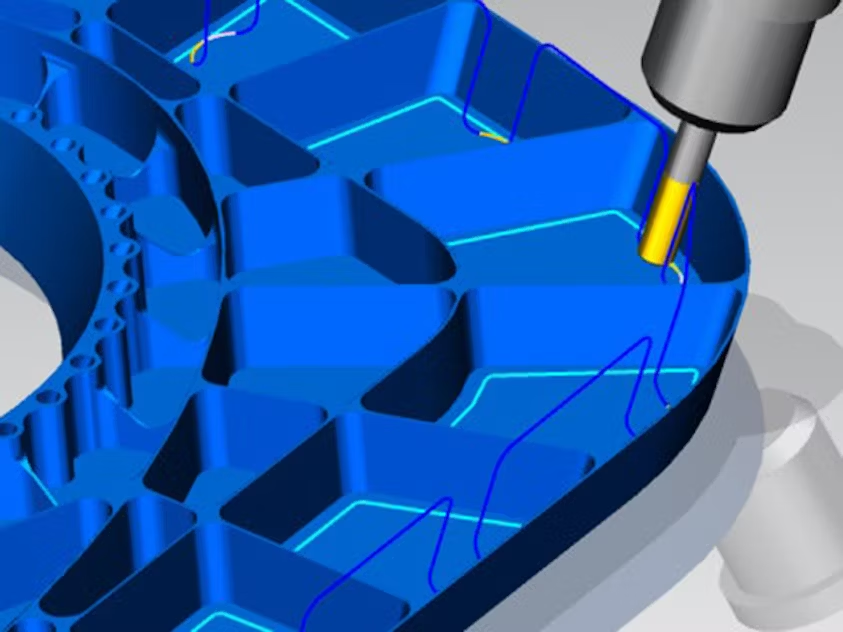

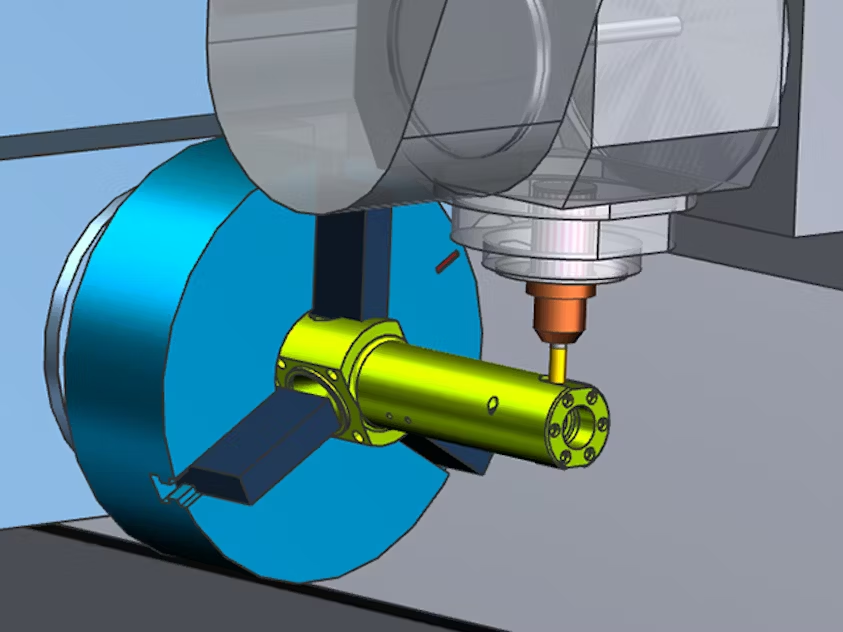

4-Axis Rotary Machining

Simplify the complex task of programming roughing operations for cylindrical and conical parts with NX’s advanced 4-axis rotary machining capabilities. With minimal input, NX automatically identifies the machining material and generates optimized milling operations tailored for efficiency and precision. Advanced toolpath controls — including tool contact shift and point density adjustments — enable smooth, highly efficient multi-axis roughing operations. The helical entry feature ensures gradual engagement with the material, enhancing tool life and improving the overall machining process. Additionally, the rest roughing capability intelligently detects and removes uncut material from previous operations, ensuring complete and consistent material removal for superior results.

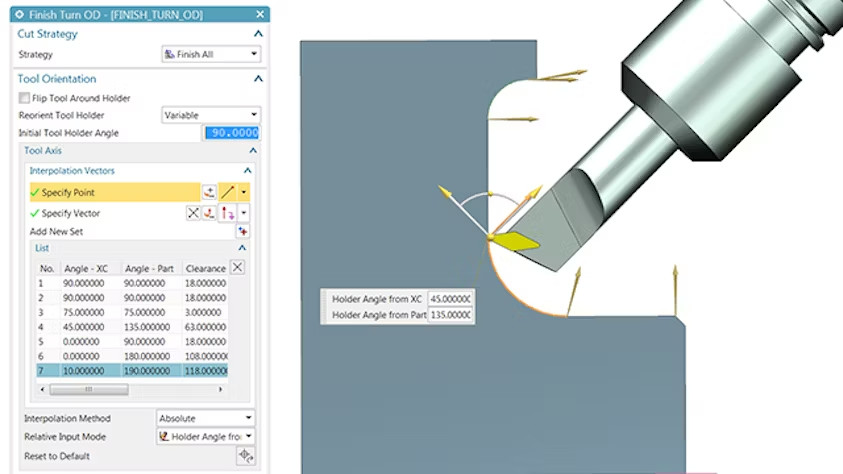

B-Axis Turning

Simplify the programming of complex parts that traditionally require multiple setups and tools with B-axis turning in NX. This advanced functionality enables you to define the tool’s variable axis orientation, allowing for greater flexibility and precision in multi-operation machining.

The advanced control settings provide precise management of the created operations. Two interpolation modes — Absolute and Relative — offer flexibility to program even the most challenging jobs on modern mill-turn machines, which combine profile turning with continuous tool axis orientation.

By leveraging B-axis turning, manufacturers can reduce the number of setups, operations, and tools required, resulting in increased productivity, reduced cycle times, and improved machining efficiency.

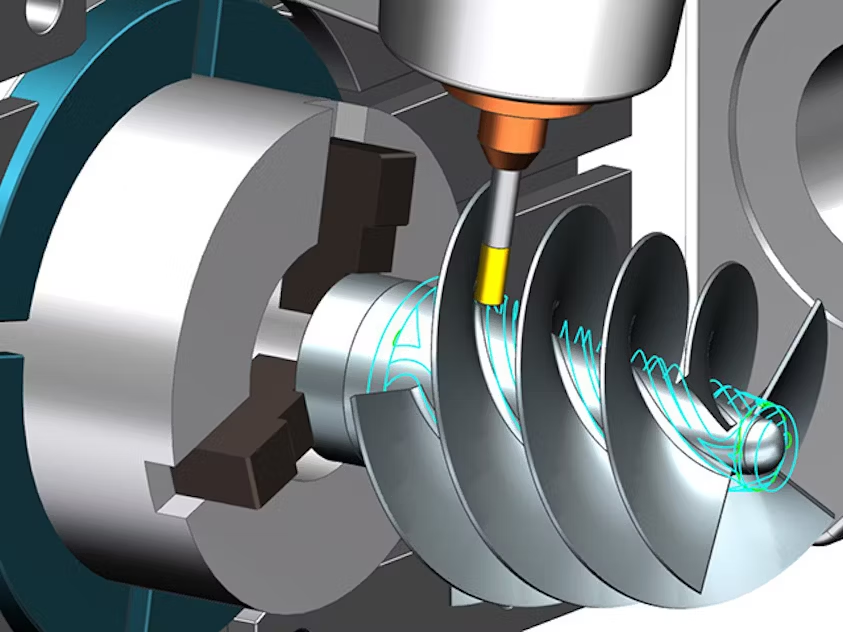

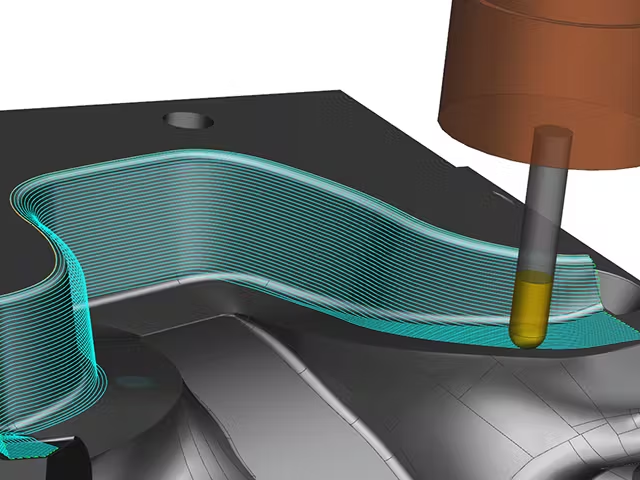

Advanced Surface Finishing

Achieve exceptional surface quality with Advanced Surface Finishing tools designed for high-precision components. The Guiding Curves feature enables precise control over tool movement by following user-defined paths, ensuring smooth transitions and flawless finishes even on the most complex surfaces.

With Surface Contouring, you can effortlessly generate toolpaths that follow the natural shape of the part, allowing for consistent and efficient finishing across intricate geometries. This ensures that fine details are preserved while maintaining superior surface integrity.

Barrel Milling further enhances finishing efficiency by utilizing large-radius tools that cover more surface area in fewer passes, significantly reducing cycle times without compromising on quality.

Together, these advanced finishing capabilities empower you to produce parts that meet the highest standards of precision and surface excellence, while achieving faster turnaround times and improved productivity.

Integrated CAD Capabilities in NX CAM

NX CAM offers industry-leading CAD tools for modeling, editing, and assembly, significantly accelerating the CNC programming process. With integrated translators, you can seamlessly import all standard data formats, including IGES, DXF, STEP, STL, and JT, ensuring smooth interoperability across different systems.

Synchronous Technology in NX enables direct editing of part models to efficiently prepare them for NC programming. You can easily close holes and gaps, offset faces, or resize part features. Additionally, it allows you to develop as-cast models or other design derivatives from existing parts by interactively pushing and pulling existing faces.

The assembly tools provide the capability to create a complete digital replica of your manufacturing setup, including the part, fixtures, table, and CNC machine. This enables the creation of optimized toolpaths that automatically avoid collisions with workholding components, ensuring safe, accurate, and error-free production.

Furthermore, full associativity between the part model and machining operations ensures automatic updates whenever design changes occur. This integrated approach enhances consistency, reduces rework, and maintains alignment between design and manufacturing throughout the production process.

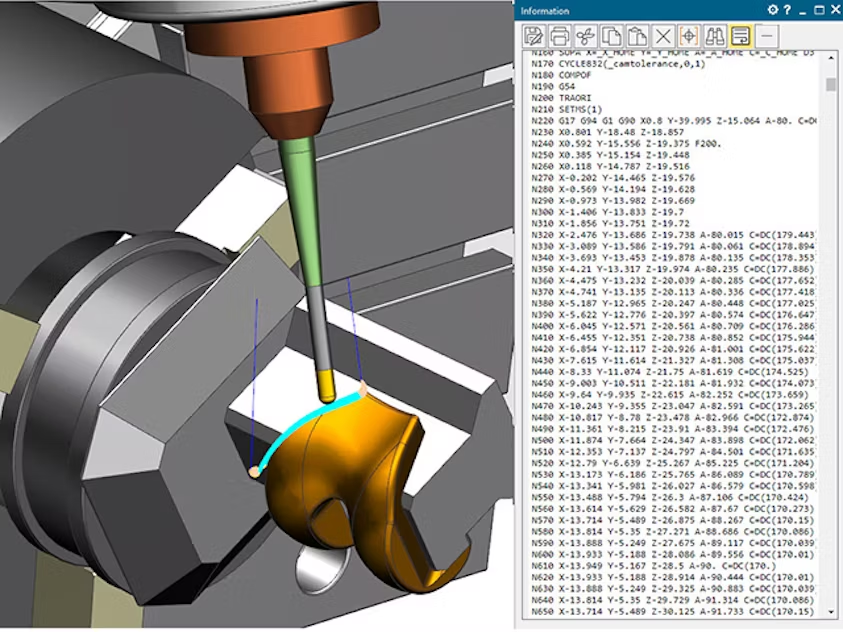

Accurate G-Code-Driven Simulation

Ensure error-free machining with G-code-driven simulation in NX X Manufacturing. This advanced simulation capability displays machine motion directly driven by the NC code output, using a detailed 3D digital model of the machine — including the part, fixtures, and tooling — to replicate exactly how the machine tool will move in real operations.

NX X Manufacturing provides multiple levels of simulation, ranging from basic toolpath verification to full-scale machining simulation that includes a complete digital twin of the machine tool. With collision checking and multi-channel synchronization performed directly from the G-code, you achieve the highest level of accuracy and confidence before production.

By performing machine simulation directly within the programming environment, NX X Manufacturing eliminates the need for separate simulation software. This streamlined workflow ensures all relevant information is available in one place, enhancing productivity, accuracy, and process reliability throughout the manufacturing cycle.

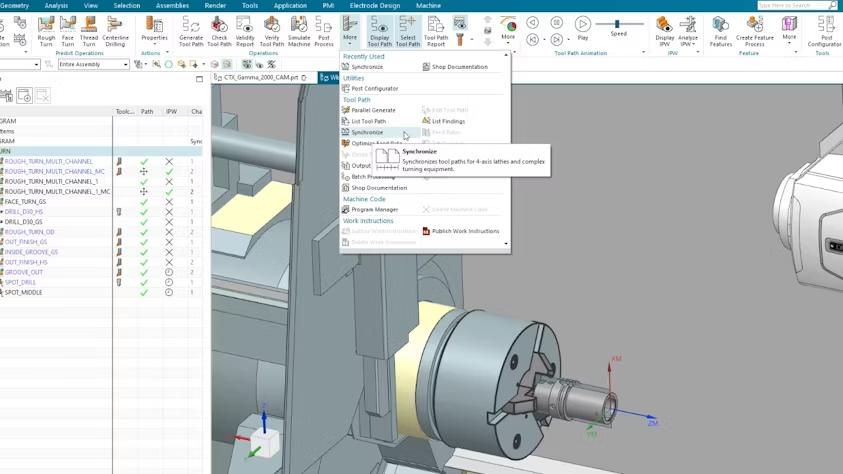

Multi-Channel Synchronization

Synchronize machining operations across multiple channels to ensure seamless coordination between tools and prevent collisions during simultaneous machining. This advanced functionality enables you to control the timing of operations, ensuring that different tools do not begin machining at the same time, thereby enhancing safety, precision, and overall performance.

Each channel represents a complete sequence of machining operations assigned to a specific spindle or tool group. To maintain precise control, you can add synchronization events that define the start and end points of each operation. These events help balance the workflow across all channels, optimizing machine utilization and significantly improving multi-channel performance and productivity.

Explore the four scalable tiers of NX X Manufacturing solutions: Essentials, Standard, Advanced and Premium

Best software for CNC programming and production

Subhashis.S, Staff Engineer, Enterprise Company

Read G2 review

Advanced capabilities for complex part machining

Mohammed S., Program Manager, Mid-Market Company

Read G2 review

Superior for 3D calculations and toolpath creation

Verified user in manufacturing, Small-Business Customer

Read G2 review

Explore related NX X Manufacturing products

Get more details about our wide range of cloud solutions for your specific part manufacturing needs.

NX X Manufacturing Standard

Automate prismatic part programming with integrated CAD/CAM technology, featuring 2.5-axis milling, hole making, turning, and on-machine probing capabilities—all seamlessly connected to industry-leading CAD tools and powered by cloud technologies.

NX X Manufacturing Advanced

Use advanced 3- and 2.5-axis milling, turning, on-machine probing capabilities among other advanced functionalities. Leverage integrated CAD/CAM tools streamline the preparation & programming of the most demanding freeform parts.

NX X Manufacturing Value Based Licensing

NX X Manufacturing add-ons are available exclusively through our innovative Value-Based Licensing model, offering a flexible and cost-effective way to extend your capabilities. Enhance your NX X Manufacturing solution with a wide range of powerful add-ons.Teamcenter Share: Cloud-Based Collaboration

Optimize your entire production process with Teamcenter Share, a next-generation, cloud-based collaboration solution from Siemens that seamlessly integrates with NX CAM. This powerful platform enables you to securely communicate and share information with both internal and external stakeholders in the cloud, ensuring smooth and efficient collaboration throughout the production lifecycle.

Connect design, manufacturing, and shop floor teams to achieve more flexible, agile, and efficient production processes. With features such as secure centralized storage and email address-based sharing, Teamcenter Share allows you to instantly and safely collaborate with colleagues, partners, and customers — anytime, anywhere.

Each subscription includes access to Teamcenter Share, along with an Enterprise Cloud Account (ECA) that provides administrators the ability to manage user access and assign privileges.

Additionally, all authorized users (excluding guest users) receive access to the “Getting Started with Siemens Xcelerator Academy” (LAAS49000) on-demand training through the Siemens Xcelerator Academy portal, ensuring a smooth onboarding experience and continuous learning for all team members.

Learn more about NX for manufacturing

Customer support

Siemens offers customer support for NX and all of our products..

Contact us

NX for manufacturing blog

Keep up with the latest news and highlights of NX for manufacturing software on our blog site.

.

Visit blog

NX for manufacturing community

Join the conversation or get answers to all of your NX for manufacturing software questions.

Visit community