Additive manufacturing

Pragmatic software for industrial-scale additive manufacturing (AM).

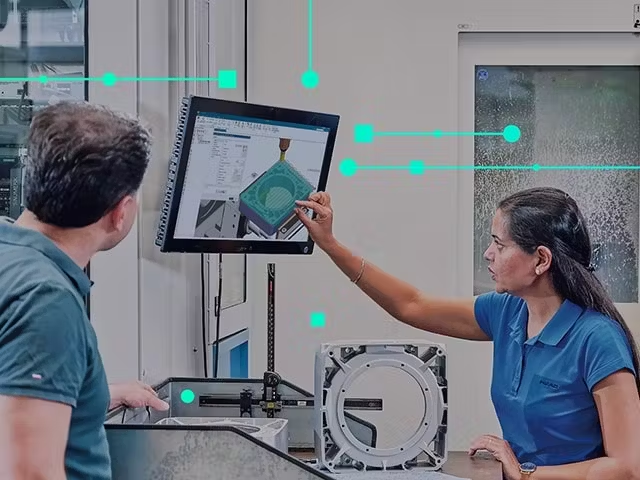

Solutions for industrializing additive manufacturing

Siemens offers a comprehensive software portfolio that enables you to manage the full spectrum of additive manufacturing.

Discover how to industrialize this process and equip your team with NX X Manufacturing, the cutting-edge cloud-powered

Software-as-a-Service (SaaS) solution.

Design for additive manufacturing

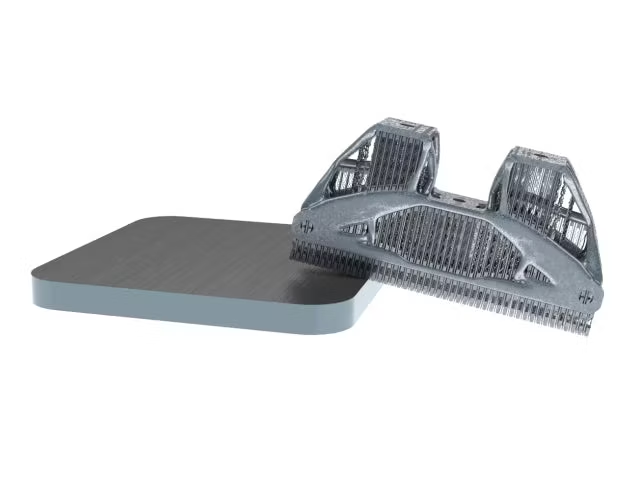

A successful additive manufacturing process starts with design. AM enables the creation of intricate designs, including optimized surfaces and lattice structures. Our solutions empower you to design and print complex geometries at scale, unlocking new possibilities for innovation.

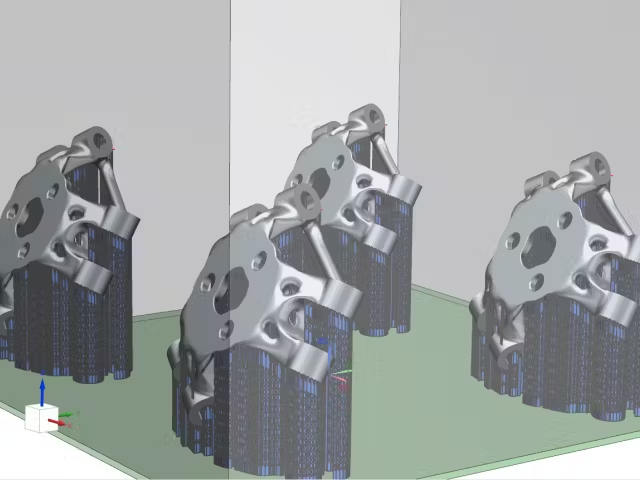

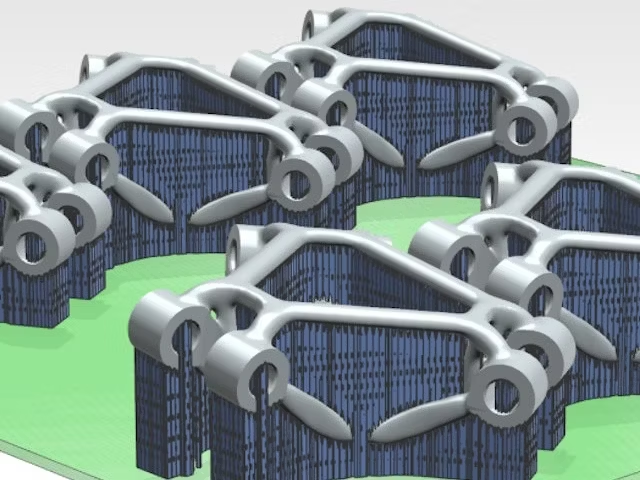

Print build preparation

Achieving high-quality, efficient results from the AM process starts with the right setup. NX’s integrated build preparation tools help you optimally place, orient, and support parts in the build tray, ensuring maximum efficiency.

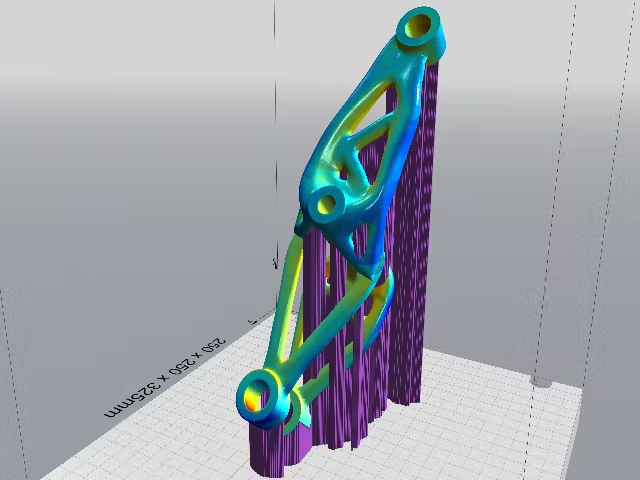

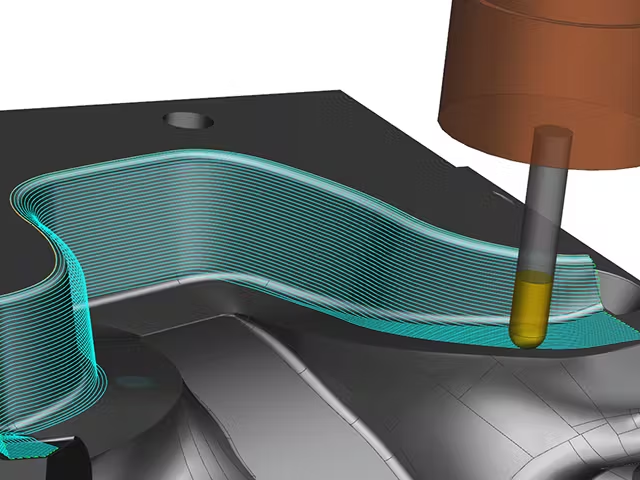

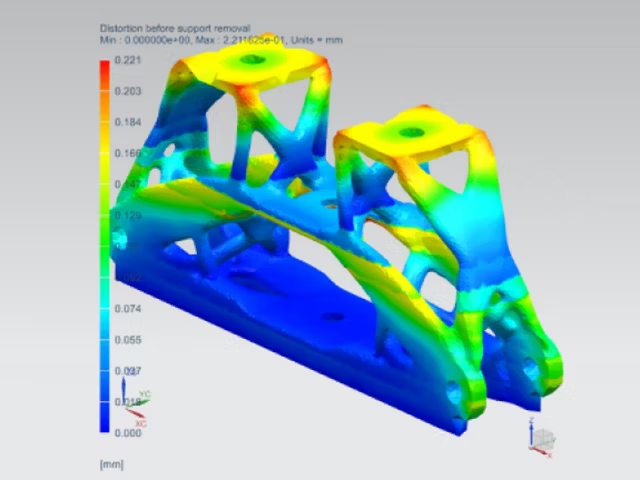

Build simulation

Simulating the build process is key to producing high-quality 3D prints at scale. With tools for optimizing build orientation and mesoscale deposition paths, NX ensures you can achieve successful prints right from the start.

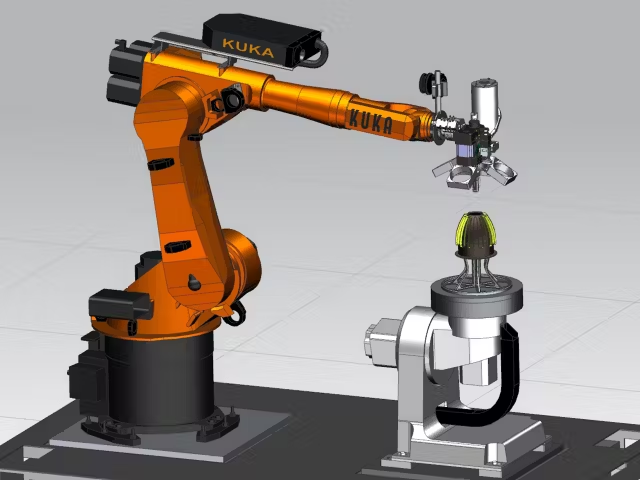

Machine connectivity

Siemens NX offers compatibility with a vast array of 3D printing hardware, covering systems such as planar powder bed, filament deposition, multi-material, and multi-axis printers.

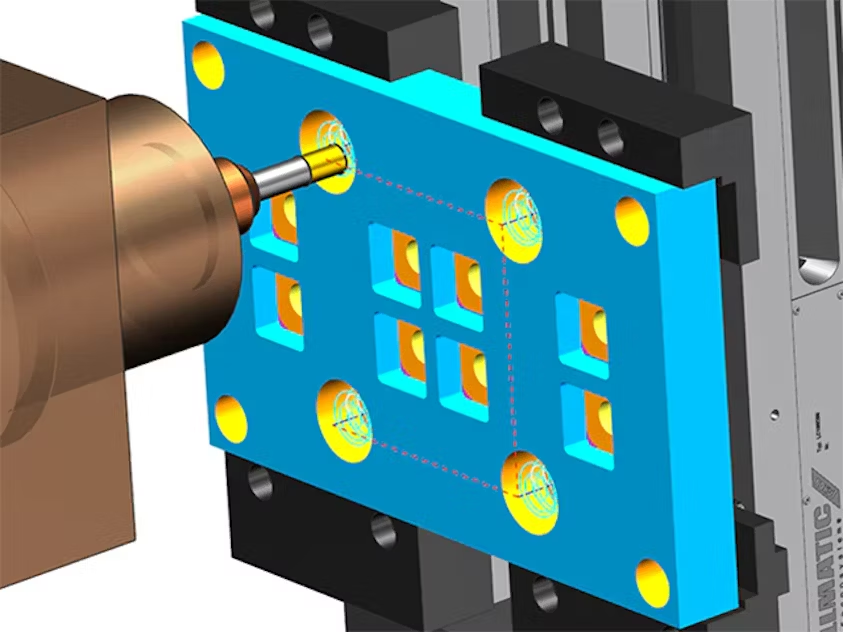

Post-print processing

Industrial-grade 3D printing demands powerful post-processing software. Printing is just one part of the additive manufacturing journey. The complete process includes powder removal, part extraction from the build tray, and post-processing machining—each step is fully supported within our additive manufacturing solution suite.

Process management

To optimize additive manufacturing production, effective process management is essential. This covers everything from order-to-shipment workflows to material management and machine scheduling. Our solutions cater to businesses of all sizes, ensuring maximum efficiency throughout the entire AM process and helping you achieve the highest return on investment from your additive manufacturing efforts.

Compare NX X Manufacturing solutions

Explore the four scalable tiers of NX X Manufacturing solutions: Essentials, Standard, Advanced and Premium

Case study

LimaCorporate

Designing 3D printed implants

with NX

Company: LimaCorporate

Location: Villanova, San Daniele del Friuli, Italy

Siemens Software: NX

Size: Medium

Extend value with NX X Manufacturing add-ons modules

Enhance your NX X Manufacturing solution with more than 20 add-ons available through our Value-Based Licensing model. These scalable, cost-effective add-ons let you tailor your manufacturing capabilities to fit specific project requirements. Whether it’s part model preparation, specialized machining, simulation, postprocessors, or machine kits, you’ll have the flexibility to optimize every aspect of your manufacturing process.