case study

Industrializing additive manufacturing

with integrated design, manufacturing,

and quality assurance

NX helps AM specialist reduce development time from weeks to days

Challenges

- Design and produce components to maximize quality and

economy - Develop the potential of

additive manufacturing - Prioritize quality assurance

Keys to success

- Implement NX software for the

entire process chain - Combine 3D printing with

CNC finishing - Leverage knowledge, experience, and enthusiasm for 3D

printing

Results

- Produced parts in days instead

of weeks - Responded to customer

requests more quickly - Improved quality

“With NX, we can manage the entire manufacturing workflow — from design and CAM programming to additive manufacturing and quality assurance — all within a single integrated software.”

— Thomas Hilger, Managing Director & Owner, Lightway GmbH & Co. KG

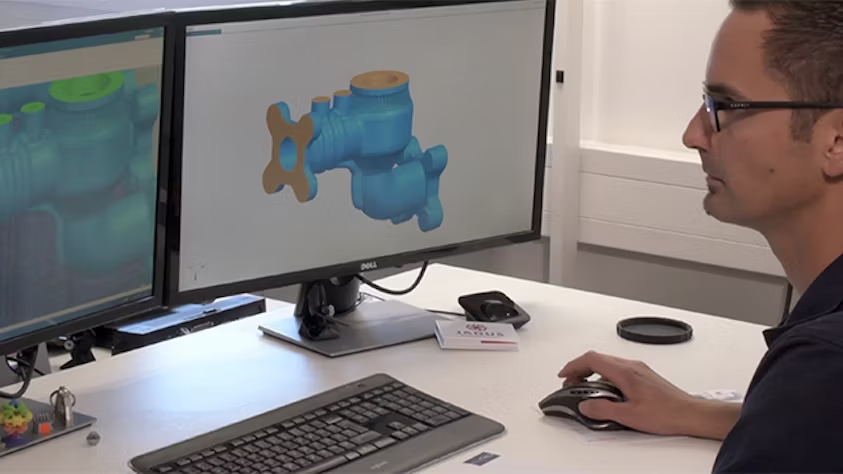

Specialists in Additive Manufacturing

Lightway GmbH & Co. KG is a young, dynamic, and innovative company based in Niederzissen, Germany. As one of the few companies in the country offering in-house expertise across design, 3D metal printing, CNC machining, and robotics, Lightway stands out as a full-service partner delivering precision-engineered parts to its customers.

“3D metal printing inspires us every day with its incredible design freedom and potential for weight reduction,” says Thomas Hilger, Managing Director and Owner of Lightway. “Customers come to us with challenges or questions about additive manufacturing. We support them throughout the entire process — from the initial idea to the optimized design for additive manufacturing, as well as final machining and finishing. Each customer receives tailored advice, and we provide the complete additive manufacturing process chain from a single source.”

The Lightway team combines deep technical expertise, experience, and passion to drive the industrialization of additive manufacturing (AM). Their engineers, technicians, and project managers thrive on innovative projects, continuously developing new applications for AM technology.

Serving clients across diverse sectors — including mechanical and plant engineering, electrical engineering, automotive, toolmaking, aerospace, and medical technology — Lightway produces a wide range of components. These include mechanical parts for cooling, heating, and media routing (such as nozzles and complex housings), as well as aerospace and automotive components like holders, sensors, hinge elements, prototype parts, and high-performance motorsport components.

Combining Additive Manufacturing with CNC Machining

Lightway seamlessly integrates 3D metal printing with CNC machining to maximize the strengths and possibilities of both technologies. This hybrid approach enables the company to achieve exceptional precision, flexibility, and efficiency in part production.

To ensure fast turnaround times and dynamic manufacturing performance, Lightway’s facility is equipped with state-of-the-art AM systems from EOS, a leading provider of industrial 3D printing equipment, and advanced 5-axis machining centers from DMG MORI.

For both additive manufacturing (AM) and computer-aided design and manufacturing (CAD/CAM), Lightway relies on NX™ software — part of the Siemens Xcelerator business platform of integrated software, hardware, and services — enabling a fully digital, connected, and optimized production workflow.

Integrated Solutions for the Entire Process Chain

With its AM-specific features and built-in CNC programming tools, NX™ software enables Lightway to maintain a fully integrated, end-to-end manufacturing process.

“We use Siemens NX for the entire workflow,” says Ingo Müller, Project Engineer at Lightway. “The design capabilities for additive manufacturing are truly impressive. From simple geometries to the most complex components — including topology optimization, lattice structures, and freeform surfaces — everything can be created and managed within a single, unified software environment.”

Designing for Additive Manufacturing

NX™ software provides Lightway with powerful tools to optimize designs specifically for the additive process. Built-in design rule checks automatically detect potential issues—such as overhangs or areas requiring support structures—helping engineers make early corrections. The integrated lattice tool enables the creation of lightweight yet structurally robust components, while generative design and topology optimization technologies allow engineers to develop complex geometries that meet key performance parameters like strength-to-weight ratio, material efficiency, and thermal or mechanical constraints.

“Siemens is a pioneer in additive manufacturing software solutions,” says Thomas Hilger, Managing Director and Owner of Lightway. “We leverage this expertise by working with the state-of-the-art NX software from Siemens right from the start.”

“We clearly benefit from the NX Additive Manufacturing module, especially with its support structure generation, component patterning, and associative updates for production,” adds Pascal Schäfer, Technical Manager at Lightway. “If small design changes occur, we don’t have to redo everything—the system updates automatically.”

Lightway also uses a Siemens-developed NX AM integration module that connects directly with EOS 3D printers, allowing engineers to prepare, position, orient, and support print jobs within the NX AM environment. Users can select EOS machines, define build strategies, and export printer-ready job files without switching software. “The EOS print integration accelerates our workflow tremendously,” says Schäfer.

Finishing with CNC Milling

For Lightway, CNC machining perfectly complements metal 3D printing, ensuring high-quality postprocessing and faster delivery for customers. By maintaining in-house machining capabilities, the company has greater control over surface quality, precision, and turnaround time. One of its key assets is a universal 5-axis simultaneous milling machine, equipped for rapid traverses and high rotary swivel speeds, enabling dynamic and efficient part processing.

Lightway’s engineers rely on NX™ software’s advanced NC programming tools to generate precise finishing programs for components produced through additive manufacturing.

“To remove support structures on the milling machine, we use cutting-edge technologies like simultaneous 5-axis machining, which Siemens NX fully supports,” says Pascal Schäfer, Technical Manager at Lightway. “This allows us to easily apply the most advanced milling processes available. For additive manufacturing, we even utilize unmanned production, using NX Robotics to prepare the appropriate robotic setup overnight for the milling machine.”

Focus on Quality

At Lightway, quality assurance is a top priority. Given the demanding precision requirements of complex components, the company employs advanced optical and tactile coordinate measuring machines (CMMs) to thoroughly inspect parts after finishing.

NX™ software strengthens this commitment to quality with its automated inspection programming capabilities. By reading part geometry and 3D model annotations, NX intelligently identifies features, dimensions, and tolerances, enabling engineers to efficiently create, validate, and execute inspection programs — ensuring every component meets the highest quality standards.

Faster Response to Customer Requests

“By utilizing NX across the entire process chain, we’ve gained significantly more flexibility in component production,” says Pascal Schäfer, Technical Manager at Lightway. “We can now respond much faster to customer requests because all our data is seamlessly connected. From the devices and AM module to CAM programming—everything updates automatically, ensuring smooth coordination and quicker turnaround times.”

From Weeks to Days

“With NX, we can now manage the entire manufacturing process—from design and CAM programming to additive manufacturing and quality assurance—within a single software platform,” says Thomas Hilger, Managing Director and Owner of Lightway. “This allows us to develop components that are impossible to achieve with other CAD systems. What once took several weeks can now be completed in just 10 days, from the initial concept to a fully functional part.”

We transformed an initial concept into a ready-to-use component in just 10 days — a process that previously took several weeks.

Thomas Hilger, Managing Director and Owner, Lightway