Buyer’s guide

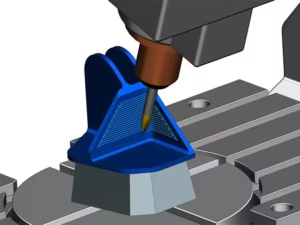

Explore how NX X Manufacturing, a cloud-based solution for part manufacturers, increases productivity by streamlining planning, collaboration, and execution—while automating and integrating CNC programming, additive manufacturing, CMM inspection, and more through a scalable, flexible platform.Driving next-generation high-quality part manufacturing

NX X Manufacturing is a cloud-based solution that eliminates traditional manufacturing limitations, enabling high-performance part production.

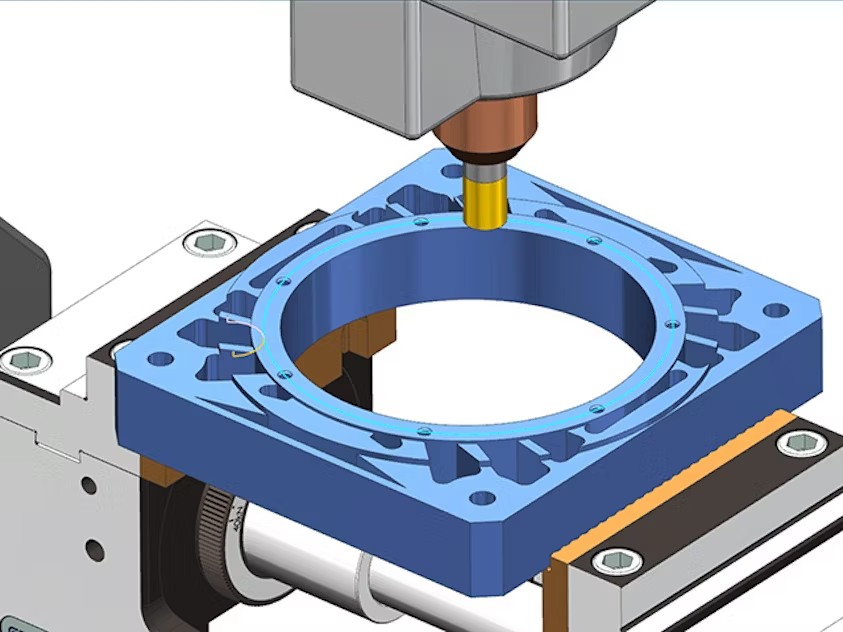

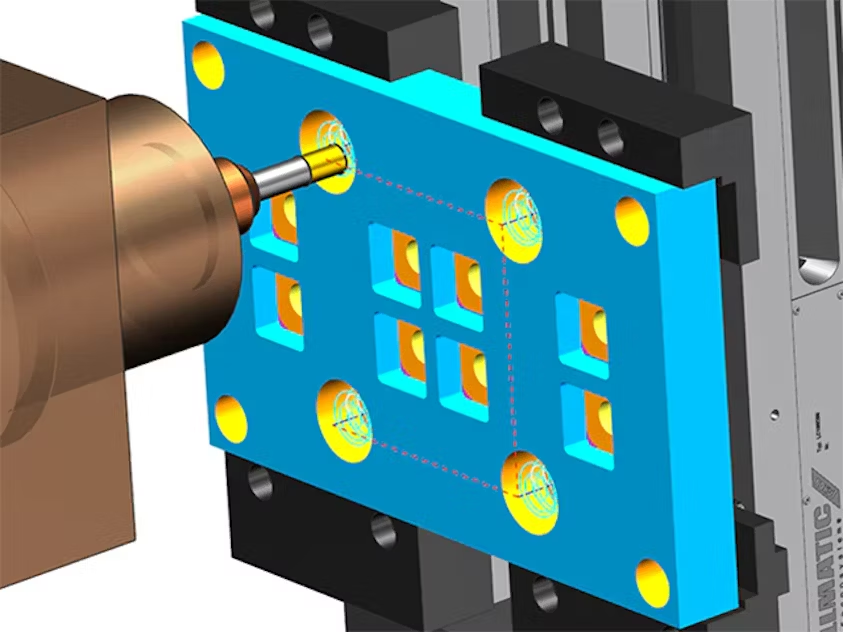

Connected Workflows: Seamlessly integrate planning, programming, simulation, and execution across CNC machining, robotics, additive manufacturing, and inspection—all in one platform.

Cost-Efficient by Design: Reduce overhead with no need for expensive infrastructure, ongoing IT support, or complex maintenance. Pay only for the licenses you need, tailored to individual users.

Flexible & Scalable: Easily adapt to changing production demands with cloud-based licensing—no more deployment hassles, version control issues, or IT headaches.

AI-Powered Productivity: Accelerate performance with digital twin technology and intelligent, cloud-enabled automation that streamlines every step of the process.

Trusted by Industry Leaders: Recognized by the part manufacturing community on G2 as a top CAM software for advanced toolpath control and automation.

Getting started with NX X Manufacturing

Flexible licensing to match your needs

NX X Manufacturing is offered in four flexible tiers : Essentials, Standard, Advanced, and Premium– designed to align with your current operations and grow with your business. Each tier delivers varying levels of powerful CAD/CAM capabilities, along with integrated tools for cloud-based collaboration, data management, and process control.

Choose the tier that matches your needs today, and scale up as your production evolves—all while minimizing IT overhead and maintenance costs through a cloud-native deployment and a pay-as-you-need licensing model.

Extend capabilities with Value-Based Licensing add-ons

Enhance your NX X Manufacturing solution with on-demand add-ons through our flexible Value-Based Licensing (VBL) model. Using token packs (available in 25, 50, and 100-token options), you can access only the features you need—keeping costs low while boosting operational agility.

Choose from a growing library of 20+ add-ons to customize your environment, including tools for part model preparation, machining productivity, simulation, specialized operations, postprocessors, and machine kits.

With new add-ons regularly added to the token pool, your system can continuously evolve with your needs. NX X Manufacturing with VBL lets you deploy the right tools at the right time—driving greater efficiency, flexibility, and value.

Integrated part manufacturing with NX X Manufacturing

NX X Manufacturing unifies design, planning, and production in a single, integrated cloud solution—empowering seamless collaboration across globally distributed teams.

Secure, Cloud-Based Collaboration with Teamcenter Share

Easily collaborate with internal teams and external partners using secure cloud sharing. Accelerate feedback and streamline coordination—without the need for complex IT infrastructure.

Built-In Cloud Data Management

NX X Manufacturing includes robust, built-in data management that stores your manufacturing data securely in the cloud. Key capabilities include version control, task assignment, tool and NC program tracking within CAM setups, and full traceability from design through manufacturing—ensuring data integrity and process visibility every step of the way.

Start your journey with NX X Manufacturing for free

This trial gives you full access to NX X Manufacturing Premium, including 100 manufacturing tokens to unlock advanced capabilities such as 2.5- to 5-axis milling and turning, integrated CAD tools, and a rich online library of machine kits, postprocessors, and machining simulation features for efficient NC programming and virtual validation. Through Value-Based Licensing, you can explore a growing selection of over 20 add-ons, allowing you to scale functionality based on your unique production needs. To ensure a smooth start, step-by-step guided tutorials are included—helping you adopt the platform quickly and start realizing value right away.

Get started with your trial today—it’s simple!

Supported Devices, OS, Platforms, and Technical Requirements

Hardware Requirements

- Processor: NX performs best on modern multi-core processors with high clock speeds. More cores don’t always mean better performance—benchmarking is recommended.

- Memory (RAM):

- Minimum: 8GB

- With Teamcenter: 12GB minimum

- For large assemblies or complex parts: 32GB+ recommended

- Storage: SSDs are strongly recommended for faster load and save times.

- Graphics Adapter: Use only Siemens-certified GPUs with OpenGL support. Consumer/gaming GPUs are not optimized for NX.

- Multiple Monitors: Supported with some limitations. Identical monitors with native resolution and horizontal scan mode are recommended.

Operating System & Software Compatibility

- Windows: Supported: Windows 10/11 Pro or Enterprise (64-bit)

- Linux: Supported only for batch processing. No interactive UI support.

- Mac OS: No longer supported (as of NX 1847).

- Embedded Browser: NX 2412 and later require Microsoft WebView2 (automatically installed).

Licensing & Installation

- License Type: Ensure the correct license is selected (Standalone, Floating, or Cloud-based).

- Teamcenter Integration: Requires additional RAM and setup for 2-tier/4-tier architectures.

- Admin Access: Installation requires Windows administrator privileges.

- Firewall & Network: IT policies must allow access to NX license servers, WebView2, and Teamcenter.

- Virtualization: Performance may be impacted. Only certified virtual environments are supported.

User Experience & Workflow

- Training: Due to NX’s complexity, prior CAD/CAM experience or formal training is recommended.

- Legacy Data: Confirm compatibility with older CAD models and third-party file formats.

- Customization & Automation: NX supports automation via NX Open and NX API. Custom scripts may require development resources.

3 steps to purchase NX X Manufacturing

NX X Manufacturing solutions—Standard, Advanced, and Premium—provide scalable capabilities for part manufacturing,ranging from prismatic machining to complex multi-axis operations, all integrated with cloud-based data management for

streamlined collaboration and enhanced efficiency.

Getting started with NX X Manufacturing

Step 1: Choose the NX X Manufacturing solution tier that best fits your needs

Unlock the full potential of NX CAM with NX X Manufacturing—bringing the flexibility, security, and scalability of SaaS to your part manufacturing operations. Choose from three preconfigured solutions—Standard, Advanced, or Premium—each designed to meet specific roles, workflows, and production requirements with powerful CNC programming, postprocessing, and simulation tools.

When NC programming capabilities aren’t required, visualize 3D part data and CAM setups including toolpaths and operations all while powered by the cloud. NX X Manufacturing Essentials serves as an ideal entry point — enabling users to visualize and interact with 3D part models and manufacturing information directly within the NX X Manufacturing environment. Extend manufacturing capabilities with add-ons for production line planning, metrology, additive manufacturing, and more.

the accuracy and consistency of everyday machining operations—perfect for job shops and production environments

digital twin verification, and cloud-based collaboration to boost productivity and achieve first-time-right manufacturing

Step 2: Extend functionality of your NX X Manufacturing solution with add-on modules via NX X Manufacturing Value Based Licensing

Expand your NX X Manufacturing capabilities with flexible add-ons available through Value-Based Licensing.

NX X Manufacturing offers over 20 add-ons to tailor the solution to your specific project needs.

These modules unlock advanced capabilities such as part model preparation, productivity enhancements,

specialized machining, simulation, postprocessing, and machine kits.

New add-ons are regularly introduced, continuously expanding the platform’s functionality.

With Value-Based Licensing, you can access these tools on demand—adding flexibility and scalability

to your manufacturing operations.

How Add-ons Work: NX X Value-Based Licensing

NX X Manufacturing add-ons are exclusively available through a flexible Value-Based Licensing (VBL) model—

offering a cost-effective way to access advanced functionality on demand. This system enables manufacturing

teams to tap into a broad range of tools as needed, whether for everyday tasks or occasional specialized use.

Using a token-based system, teams purchase a shared pool of tokens. Each add-on has a specific token value,

which is temporarily deducted while the module is in use. Tokens are returned to the pool when the user closes

the module or ends the session, maximizing flexibility and resource efficiency.

Step 3: Purchase your NX X Manufacturing solution and NX X Manufacturing Value Based Licensing tokens

Once you’ve selected the right NX X Manufacturing solution and the add-ons that match your needs, you can purchase both the software and Value-Based Licensing tokens through the e-store or by contacting our sales team.

General NX X Manufacturing FAQs

NX X Manufacturing is a software-as-a-service (SaaS) solution that integrates cloud-based entitlement, configuration, data management, and updates with a local installation of NX Manufacturing. In practice, This means:

- The software is installed locally on the user’s workstation, delivering optimal speed and accuracy for toolpath calculations and simulations.

- Entitlement, licensing, and configuration are managed in the cloud, enabling effortless access and automatic updates without manual setup.

- Data management is centralized in the cloud, allowing secure storage and easy access to manufacturing data, tool libraries, and postprocessor configurations from anywhere.

- Automatic software updates ensure users always have the latest capabilities—no manual installations required.

This hybrid architecture combines the power of local computing with the scalability, security, and flexibility of the cloud, providing a modern and efficient manufacturing solution.

NX X Manufacturing delivers scalability, security, and simplified deployment, empowering part manufacturers with flexible licensing, automatic updates, and remote access. This approach lowers IT overhead while enabling faster, more efficient collaboration between engineers, programmers, and machine operators.

“Yes, NX X Manufacturing integrates with a range of digital manufacturing solutions, including additive manufacturing (AM), robotics, advanced CAD, and CMM inspection. It also works seamlessly with Teamcenter for Manufacturing and other Siemens Xcelerator offerings, creating a connected digital thread that links design, engineering, and production. This integration guarantees data continuity and enhances overall manufacturing efficiency.”

NX X Manufacturing adopts the same continuous release approach as NX, delivering regular updates that bring new features, improvements, and cloud-based innovations. Siemens consistently provides frequent updates, ensuring users have immediate access to the latest manufacturing technologies without the need to wait for major version upgrades.

Absolutely, Siemens Xcelerator Academy provides specialized learning modules and enablement courses designed specifically for NX X Manufacturing users. The curriculum includes topics like cloud-based CAM programming, toolpath optimization, and smooth integration with Teamcenter X for effective manufacturing data management.

NX X Manufacturing Value-Based Licensing FAQs

NX X Manufacturing Value-based Licensing provides a flexible and scalable way to access a wide range of advanced capabilities through a shared token pool. Each add-on uses a predefined number of tokens, which are automatically returned to the pool when the module is closed or the session ends—ensuring efficient and controlled resource management. With access to more than 20 add-ons, including part model preparation, advanced machining, postprocessing, and more, manufacturers can customize functionality to fit their specific requirements while aligning software expenses with actual usage. This model also includes continuous updates and the NX X Manufacturing Chat Co-Pilot, delivering intelligent in-app assistance to help boost productivity and maximize value.

NX X Manufacturing Value-Based Licensing offers flexible access to a broad set of advanced manufacturing capabilities through a token-based system.

This model includes:

- Turbomachinery Milling: Sophisticated strategies for machining complex rotating components

- Postprocessing: Efficient NC code generation tailored to various machine types

- Machine Simulation: Accurate virtual validation of machining processes

- Part Model Preparation: Tools to refine and optimize CAD models for manufacturing

- Productivity Enhancements: Features designed to accelerate and simplify CAM programming

With this scalable approach, manufacturing teams can tap into the capabilities they need, when they need them—maximizing efficiency while controlling costs.

NX X Manufacturing add-ons are offered exclusively through the Value Based Licensing model, providing a cost-efficient and highly flexible way to access advanced capabilities. Manufacturing teams can tap into a broad range of tools—whether they’re required daily or only on occasion.

Using a simple check-in/check-out system, organizations purchase a pool of tokens. Each add-on is assigned a specific token value, which is deducted from the pool when in use and automatically returned once the session ends.

These add-ons span a wide array of functionalities, including part model preparation, productivity enhancements, specialized machining, simulation, postprocessing, and machine kits.

Yes, the Value Based Licensing system is seamlessly updated with each NX X Manufacturing release, ensuring users always have access to the latest CAM capabilities without the need for additional installations

Customers begin by purchasing a base NX X Manufacturing subscription, then choose a Value Based Licensing package with the desired number of credits. These credits unlock access to advanced machining, additive manufacturing, advanced CAD, robotics, CMM inspection, machine simulation, and postprocessing capabilities—enabling flexible usage tailored to specific production requirements.

Value Based Licensing enables floating access, allowing tokens to be shared across the team so multiple users can leverage advanced manufacturing capabilities as needed.

Additional costs may be incurred if extra tokens are needed to access extended functionality or if custom postprocessors are required for specific CNC machines. However, regular software updates are included as part of the subscription.

NX X Manufacturing Value-Based Licensing FAQs

Built-in data management will soon be available and included with all Standard, Advanced, and Premium core seat license options—no additional purchase required. This new capability is planned for introduction in the next release.

The following built-in data management capabilities will be available through NX X Manufacturing:

- Cloud-enabled machining, additive manufacturing, and inspection data management

- Document management

- Check-in and check-out control

- Standard visualization with 3D markup

- Revision and single-step release management

- Revision configuration

- Where-used tracking

- Discussions and task management

- Updates and system integration

- Onboarding guide

Multi-user notification service for real-time design change alerts (token enabled)

Yes, every NX X Manufacturing seat includes built-in data management. However, if you’re already using on-premises Teamcenter, Teamcenter X, or storing data directly to the operating system, you can continue with your existing setup.

You have several data storage options with NX X Manufacturing:

- Teamcenter X: Data is stored in a single-tenant cloud environment.

- Built-in data management: Data is stored in a multi-tenant cloud environment within your enterprise cloud account.

- On-premises Teamcenter: Data is stored within your existing Teamcenter infrastructure.

NX X Manufacturing leverages advanced cloud technologies to ensure robust data protection and security. Its security and integrity have been independently verified through third-party testing. For more information on how Siemens safeguards your data, visit the Siemens Trust Center.