The executive’s guide to digital manufacturing for machine shops

Today’s manufacturing leaders understand that the future is digital

and that embracing digital manufacturing is key to overcoming production complexity and driving business growth.

By connecting innovative product design with world-class performance, digital manufacturing empowers machine shops to achieve:

- Faster speed-to-market

- Lower production risks

- Higher profit margins

- Stronger competitive positioning

In this eBook, discover the growing challenges faced by the part manufacturing industry and see how leading machine shops are leveraging digital manufacturing to transform operations, boost efficiency, and stay ahead of the competition.

Learn directly from manufacturing leaders tackling today’s toughest challenges

Excerpt from the eBook:

Germany-based EDAG Group, a leading automotive industry supplier, discovered that time-to-market cannot be compromised even when adopting cutting-edge bionic designs and additive manufacturing technologies. With the rapid shift toward automotive electrification, EDAG’s mission is to stay competitive by embracing innovation.

By leveraging digital twin technology, EDAG unified generative engineering, simulation, and 3D print preparation within a single digital ecosystem.

The results were remarkable:

Design time reduced by 50%

Streamlined processes from concept to production

“We demonstrated that additive manufacturing is also suitable for high-volume production to solve real challenges in the automotive industry.”— Sebastian Flügel, Scalebat Project Leader, EDAG

The Advantage of Using One Solution for Part Manufacturing

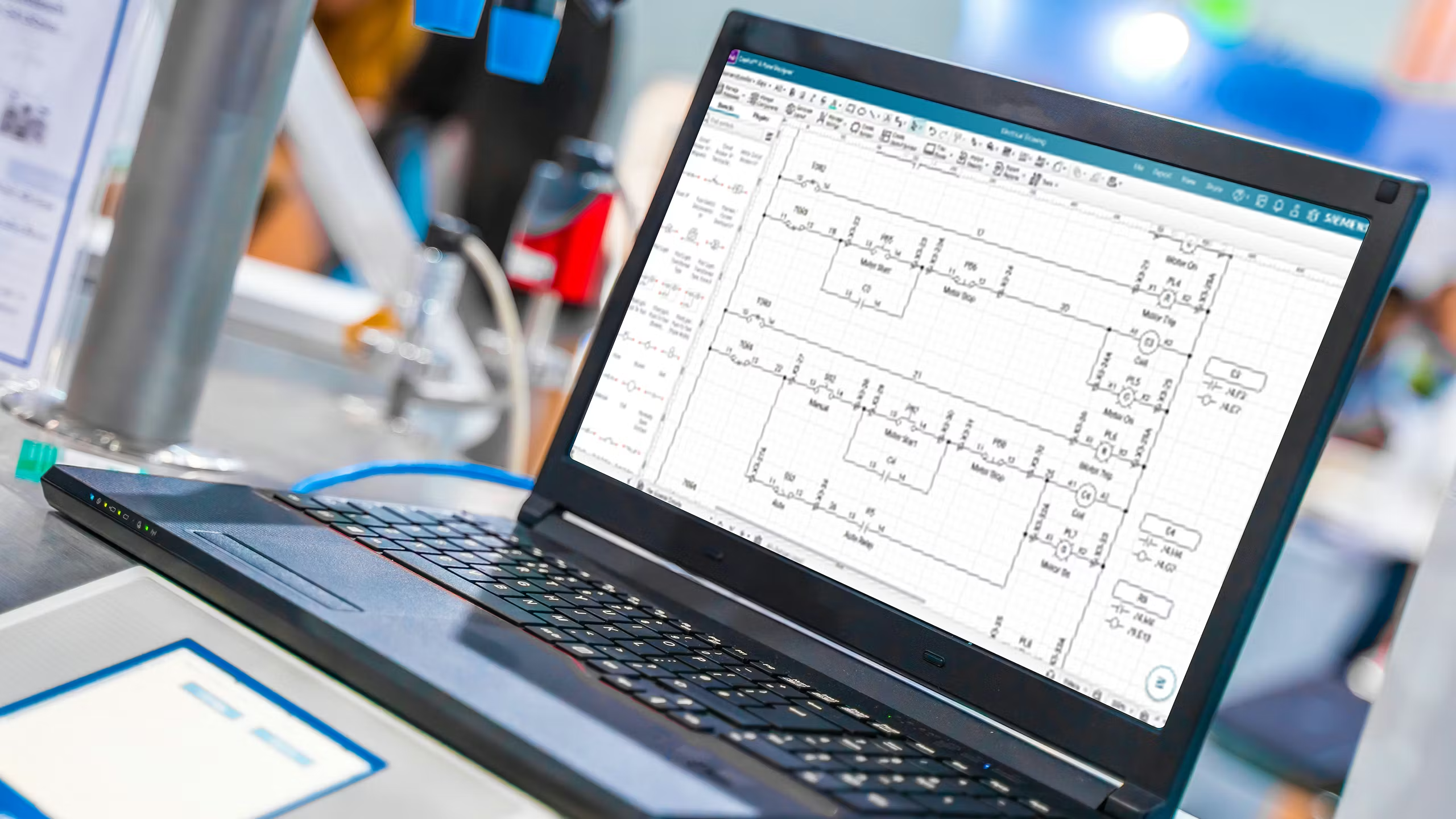

Modern part manufacturing becomes more efficient and connected with Siemens NX™, an all-in-one solution that delivers seamless integration from digital design to final production.

With NX, manufacturers can:

Streamline the entire manufacturing workflow — from 3D digital models to finished parts.

Automate CNC programming using advanced, feature-based machining and intelligent process recognition.

Control robotic cells and drive 3D printing operations directly within the same platform.

Simulate and verify manufacturing processes to eliminate errors before production.

Monitor product quality in real time for continuous improvement.

By unifying design, engineering, and manufacturing in one digital ecosystem, NX empowers part manufacturers to accelerate production, reduce costs, and achieve higher precision — all while staying agile in today’s fast-changing industry.

Innovative Moldmaker iMFLUX Uses Digital Manufacturing to Stay Ahead

iMFLUX, a forward-thinking moldmaking company, is redefining efficiency by combining machine learning, advanced software, and a state-of-the-art machine shop. With Siemens NX™ and Teamcenter®, iMFLUX has accelerated its mold design-to-manufacturing process — achieving improved part quality, lower costs, and shorter lead times.

By adopting Siemens’ integrated digital manufacturing solutions, iMFLUX has:

Automated mold processes to increase productivity and consistency.

Captured and reused company knowledge for continuous improvement.

Connected people, systems, and resources across departments for seamless collaboration.

The result? A flexible, intelligent, and future-ready production environment. Siemens’ digital manufacturing technology empowers iMFLUX to adapt to tomorrow’s challenges today, keeping them ahead in a rapidly evolving industry.