Leverage the full potential of automotive manufacturing

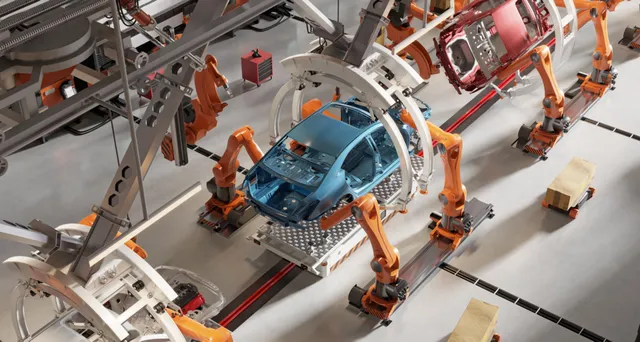

Mobility is evolving at an unprecedented pace. Trends such as electromobility, decarbonization, vehicle connectivity, and autonomous systems continue to challenge the automotive sector. With Siemens Xcelerator and the Digital Enterprise, automotive companies can reshape their business models, achieve growth and sustainability targets, and move confidently toward a more sustainable future.

Turn complexity into opportunity : by using digitalization to tackle the challenges of modern automotive manufacturing.

Automotive companies must balance numerous pressures to stay competitive: software-driven innovation is increasing complexity, evolving sustainability regulations require credible net-zero strategies, and the entire value chain must become more adaptable and sustainable. Digitalization provides the foundation to meet these demands, enabling agile, intelligent manufacturing processes that enhance sustainability without sacrificing quality or cost.

Unlock the full potential of the automotive industry

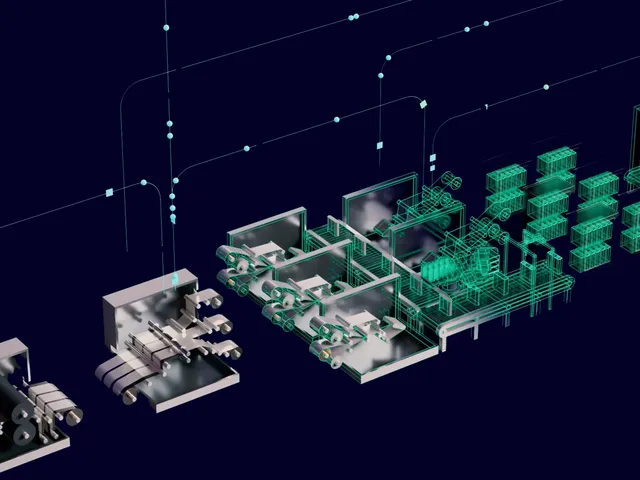

Integrate the physical and digital worlds to future-proof your entire value chain—from design and production to end-of-life recycling.Create a scalable greenfield facility in under two years and accelerate digital factory development by 50%

Rely on a single unified source of requirements, goals, and issue tracking from concept to validation and production.

Eliminate assembly mistakes, improve workflow efficiency, and repurpose proven designs to accelerate new product development.

Stay ahead of the competition by successfully transforming your business

By uniting the physical and digital worlds and streamlining processes through Digital Threads, Siemens Xcelerator enables automotive companies to accelerate their transformation into Sustainable Digital Enterprises and strengthen their competitive position. Digital Threads provide traceable, digitalized workflows across product and production lifecycles. Along these workflows, Siemens delivers comprehensive solutions that support automotive companies on their journey toward becoming Sustainable Digital Enterprises.

Let‘s automate automation

Visit us at SPS 2025 – onsite in Nuremberg, Germany and online. In hall 11, you‘ll find showcases and innovations for the process and manufacturing industries, a daily stage program and insightful Guided Tours. Experience state-of-the-art automation technology tapping into the vast potential of AI, Digital Twins and much more.Find your solution for transforming automotive manufacturing with industry-specific use cases

Next-level data management

Predictive Maintenance

Virtual verification and optimization

Next-level data management

Sustainability in the automotive industry

Your fast lane to smart buildings

Our references in the automotive industry

Top flexibility. Tight space. Super-fast.

Siemens provided innovative conveyor technology solutions for producing the Porsche Taycan. The new Taycan production facility was built at the heart of the existing sports car plant in Zuffenhausen.Learn more

Sustainable Factory Planning with Mercedes-Benz

Mercedes-Benz and Siemens have collaborated to develop a Digital Energy Twin to optimize factory energy planning, with the goal of powering all wholly owned production sites with 100% renewable energy by 2039. Siemens will provide ongoing support, training, and maintenance to enable global deployment across Mercedes-Benz’s production network.Learn more

Technology standard for eCar production

Volkswagen has partnered with Siemens to establish a technology standard, targeting high levels of automation—89% in the body shop and 28% in assembly. This standardization provides a foundation for further digitalization opportunities.Learn more