NX for manufacturing

NX X Manufacturing Value Based Licensing (50pk)

Add-ons are provided through our Value Based Licensing model. Extend your solution’s capabilities with the NX X Manufacturing Value Based Licensing (50-pack).

₹923,306.11

INR

per quantity / per year

Only ₹76,942.18 per month

You’re viewing products and pricing for India

Change country

Call us at:

Manufacture without compromise

Enhance your NX X Manufacturing solution with add-ons powered by Value Based Licensing.

Choose from a growing library of over 20 add-ons designed to tailor NX X Manufacturing to your project’s unique requirements. These add-ons deliver powerful capabilities—from part model preparation and productivity improvements to advanced machining, simulation, postprocessing, and machine kits.

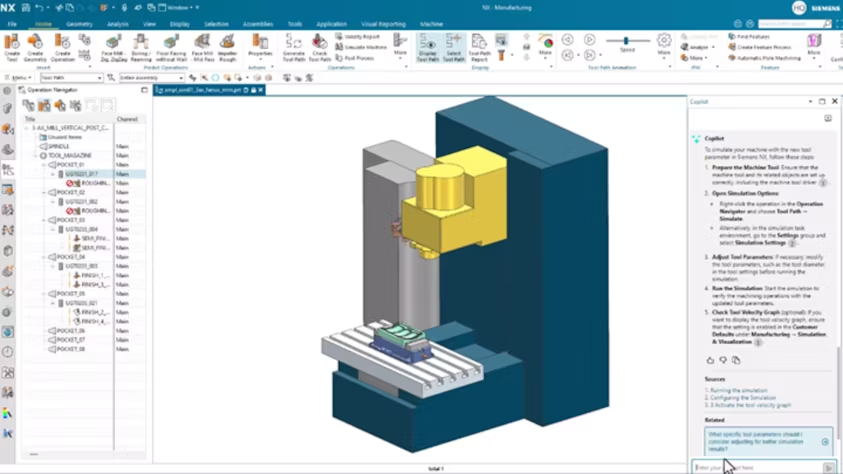

NX X Manufacturing Value Based Licensing also includes an intelligent Chat Co-Pilot that assists NC programmers with contextual guidance, documentation links, and relevant insights—helping reduce setup time and boost productivity.

We continue to expand our add-on portfolio, ensuring you always have access to the latest tools and innovations. New modules are seamlessly added to the Value Based Licensing token pool, making it easy to scale your capabilities as your needs evolve.

How add-ons work

NX X Manufacturing add-ons are available exclusively through our innovative Value Based Licensing model—offering a cost-effective and highly flexible way to access advanced capabilities. Manufacturing teams can easily leverage a wide range of tools, whether they’re needed every day or only for specific projects.

With this model, your team simply purchases a shared token pool. Each add-on or tool has an assigned token value. When a user checks out an add-on, its token value is temporarily deducted from the pool; once it’s released, those tokens automatically return to the pool for others to use. This flexible, check-in/check-out system ensures you get maximum value and efficiency from your software investment.

Featured add-ons

The NX X Manufacturing Chat Co-Pilot is an intelligent assistant that supports NC programmers by helping them navigate NX software and resolve domain-specific queries. It streamlines workflows, reduces programming time, and boosts overall productivity on the shop floor.

Available through Value-Based Licensing for both NX X Manufacturing and NX X Design, the Co-Pilot integrates seamlessly within the NX interface. It provides contextual guidance, documentation links, and related insights. Easily activated through the search bar, it’s an invaluable tool for enhancing efficiency in programming and simulation tasks.

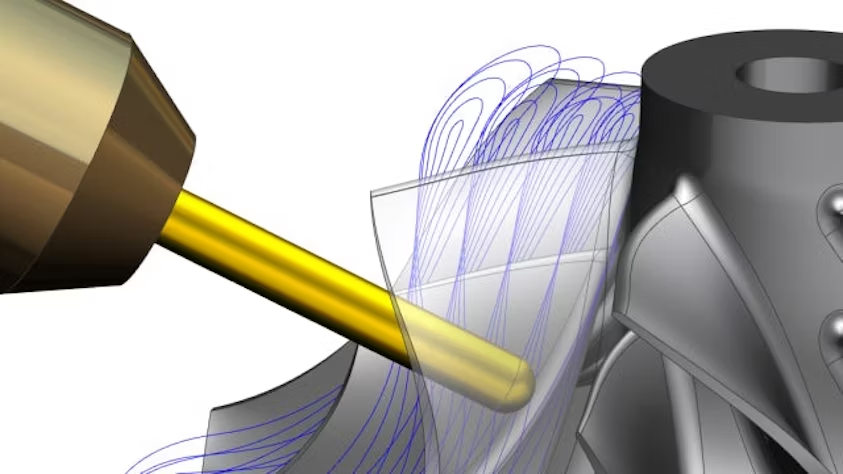

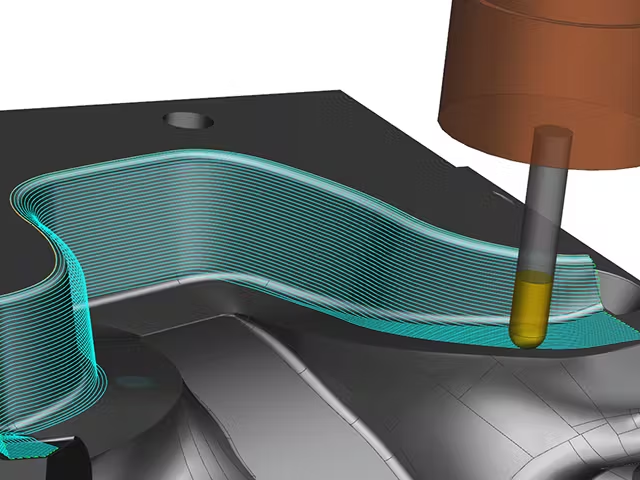

Turbomachinery Milling streamlines NC programming for complex multi-bladed components such as blisks and impellers. Advanced 5-axis roughing and automated rest milling efficiently remove material between blades, while specialized finishing strategies for hubs, blades, and splitters utilize optimized cut patterns, toolpath smoothing, and tool-axis stabilization to ensure superior surface quality.

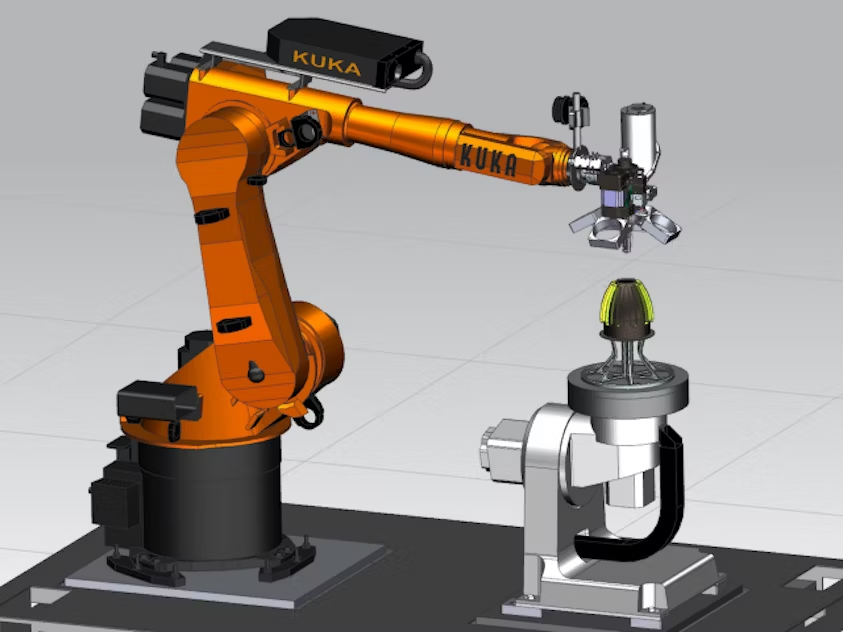

NX CAM Robotics Programming enables precise multi-axis robot programming for operations like trimming, deburring, and polishing. Robots can also be programmed for pick-and-place applications—including machine tending and tool loading—supporting efficient, unattended manufacturing.

Machine Line Planner enhances high-volume production of complex, feature-rich parts by allowing users to program, balance, distribute, and simulate operations across multiple setups and machines for optimal efficiency and throughput.

Achieve error-free machining with G-code–driven simulation that visualizes actual machine motion based on NC code output. The full 3D machine model—including the part, fixtures, and tooling—moves exactly as it will on the shop floor, ensuring precise verification before production.

With Sinumerik Collision Avoidance, potential collisions are continuously monitored in real time, improving operator safety and minimizing downtime. Running machine simulations directly within the programming environment provides instant access to critical information—eliminating the need for separate simulation software.

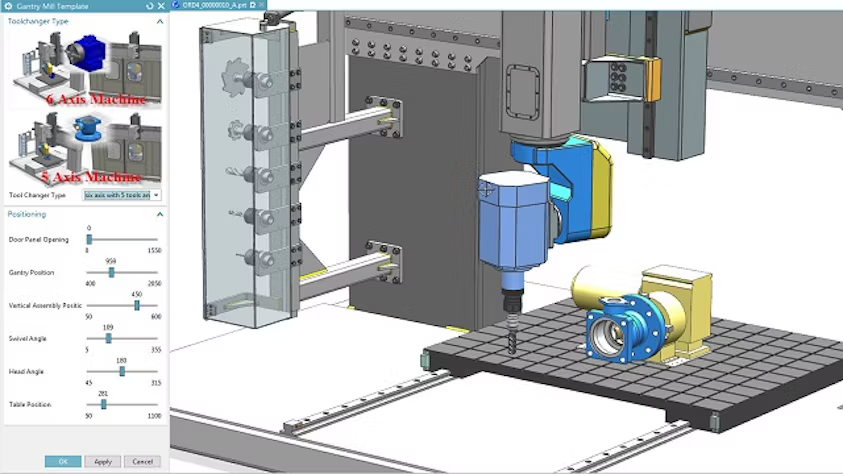

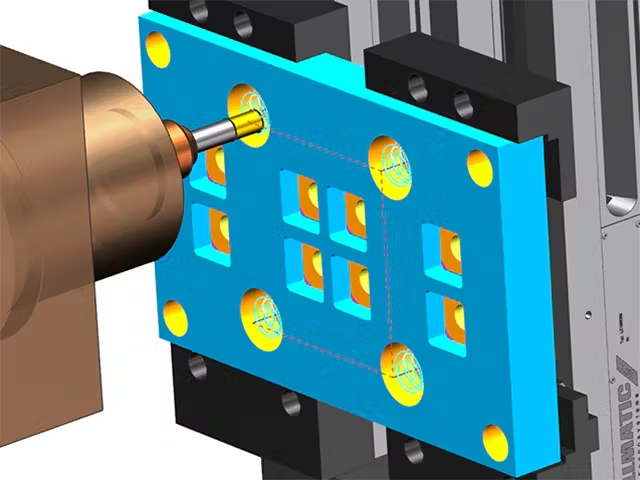

Generate machine-specific Computer Numerical Control (CNC) programs using Smart Machine Kit Solutions (SMKS)—comprehensive, preconfigured packages that include production-ready machine tools and postprocessors. SMKS are available through Post Hub, a modern cloud-based platform for streamlined postprocessing.

The Post Configurator enables you to create and customize postprocessors to meet your specific requirements, ensuring accurate generation of machine-specific NC programs.

Unlock the full potential of Synchronous Modeling, which provides powerful tools for directly editing solid faces, enabling flexible design changes and rapid modifications. This capability helps programmers quickly prepare part models for NC programming and accelerates the development of as-cast models.

Capture Product and Manufacturing Information (PMI)—including geometric dimensioning and tolerancing (GD&T), surface finishes, and material specifications—to define manufacturing requirements. PMI can also be leveraged in Feature-Based Machining to further automate the programming workflow.

Generate precise 2D engineering drawings that remain fully associative with your part models. Features include automatic view creation, hidden line processing, and automated parts lists, while templates streamline the generation of borders and layouts for consistent documentation.

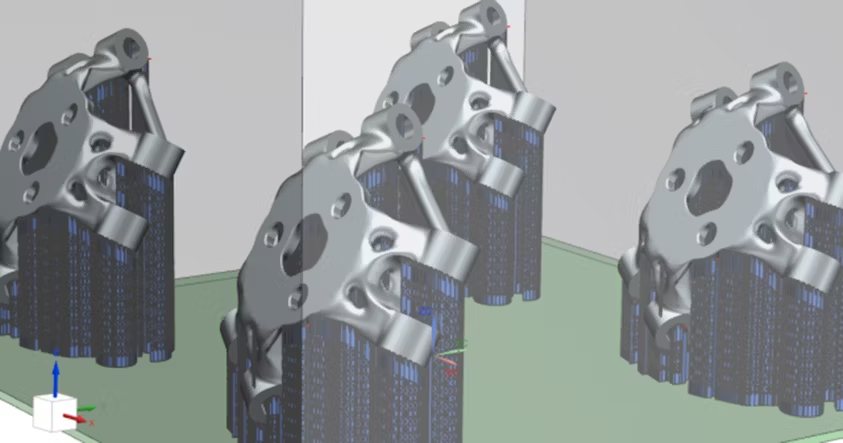

Accelerate fixed-plane additive manufacturing with NX AM Fixed-Plane solutions, supporting technologies like powder bed, jetting, MJF, and FFF.

Set up your build tray, create basic supports, and manage builds with the integrated build processor framework. Prepare and edit models using NX CAD tools, including synchronous modeling, and assemble multi-part designs for printing.

Enhance productivity with advanced support geometries such as gusset, contour, web, cone, volume, and custom supports.

Achieve simultaneous 5-axis AM path planning for robots and machine tools, combining additive and subtractive operations in a single, efficient setup.

Optimize and validate multi-axis machining with digital twin–powered simulation, and maximize output with modular CNC systems controlling up to 93 axes across 30 channels.

Explore related NX X Manufacturing products

Get more details about our wide range of cloud solutions for your specific part manufacturing needs.

NX X Manufacturing Standard

Automate prismatic part programming with integrated CAD/CAM technology, featuring 2.5-axis milling, hole making, turning, and on-machine probing capabilities—all seamlessly connected to industry-leading CAD tools and powered by cloud technologies.

NX X Manufacturing Advanced

Use advanced 3- and 2.5-axis milling, turning, on-machine probing capabilities among other advanced functionalities. Leverage integrated CAD/CAM tools streamline the preparation & programming of the most demanding freeform parts.