NX AM Multi-Axis

Provides the solutions necessary to setup and drive multi-axis and hybrid additive machines Contact us to learn how to purchase this product in India Change country Call us at :

Why NX AM Multi-Axis?

Operating multi-axis additive manufacturing hardware requires specialized software. Conventional planar 3D printing tools aren’t capable of producing the intricate, three-dimensional deposition paths needed for multi-axis printing. The NX Additive Manufacturing (AM) Multi-Axis solution provides the advanced capabilities to make this possible.

Create complex, 3D deposition paths

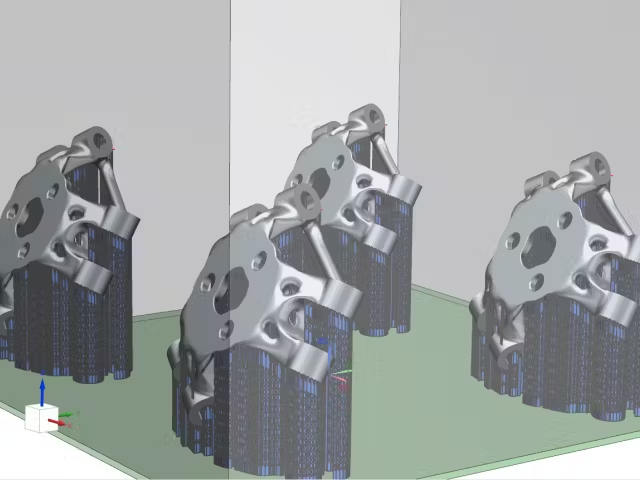

Control complex deposition paths for multi-axis additive hardware using a combination of proven, pre-programmed patterns—such as helixes. The software also enables advanced path planning for specialized applications like cladding. These intricate motion paths are extremely difficult to generate accurately with conventional tools.

Access advanced AM path planning, validation and manufacturing preparation tools such as:

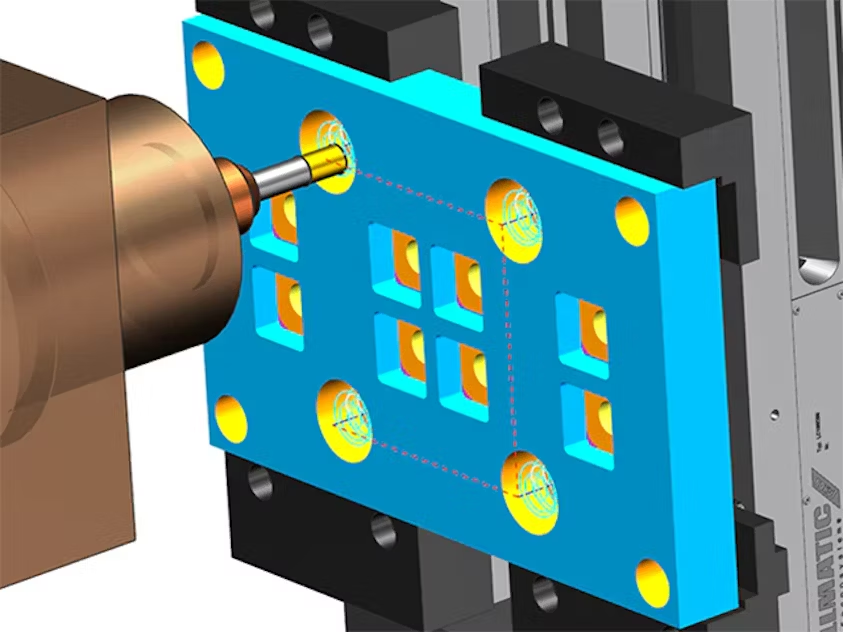

- A complete CAD tool set for feature decomposition, stage modeling and fixture design to setup jobs in your machine’s kinematic environment

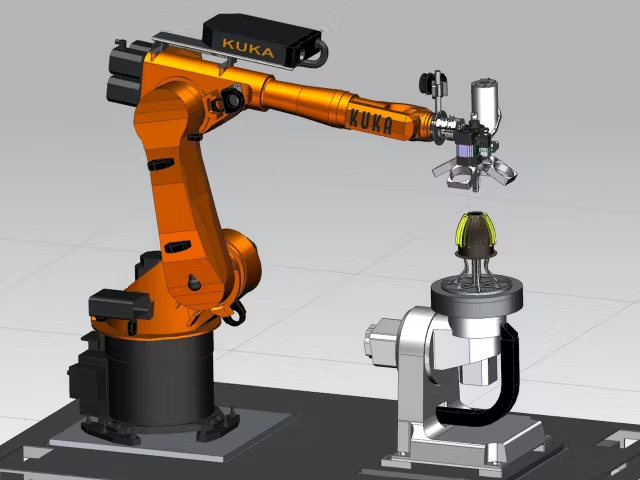

- Comprehensive simultaneous 5-axis AM path planning for robots and machine tools, supporting a wide range of tool path operations

- A powerful system to combine multi-axis deposition and subtractive manufacturing

operations in the same tool path setup - A simulation system to validate your multi-axis AM machining setup and analyze its performance via a production digital twin

- Highly productive, modular CNC automation systems controlling up to 93 axes in 30 machining channels

Featured capabilities

NX AM Multi-Axis provides a comprehensive CAD toolset designed to streamline every stage of additive manufacturing preparation. This includes powerful tools for feature decomposition, stage modeling, and fixture design, enabling efficient setup of jobs within your machine’s kinematic environment.

Feature decomposition, a key capability, allows you to break down complex part features into individual additive operations — a crucial step in generating accurate output for multi-axis and hybrid additive manufacturing.

With these integrated tools, you can accelerate part preparation for toolpath programming and simulation, ensuring faster turnaround and enhanced flexibility to adapt quickly to any design changes.

The NX AM Multi-Axis solution includes a robust set of path types for planning the execution of your multi-axis or hybrid print, including planar deposition, rotary deposition, freeform deposition and tubular deposition.

Deposition operations can be easily reordered to enable the utilization of different parameters on infill vs finish passes, to reorder multiple bodies into an optimum build solution, or to accommodate the printing of different materials.

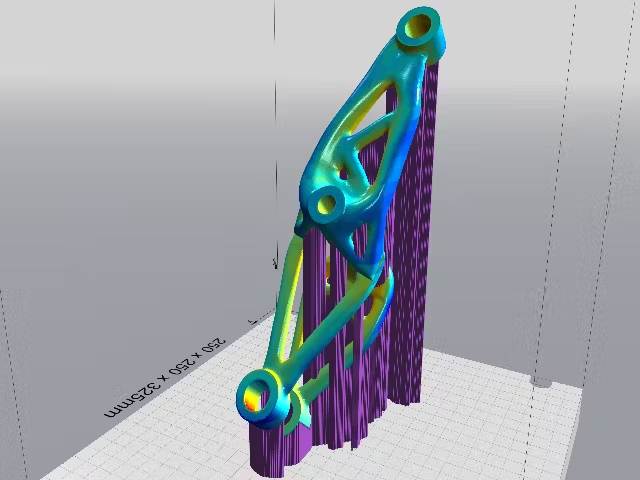

Deposition simulation then allows you to visualize the deposition of the material, helping you to identify areas where material is missing, verify the deposition process, and to prevent collisions with the deposition head.

Below is a short description of various deposition path types available in NX AM Multi-Axis and their advantages.

Planar deposition:

Build planar levels with zigzag or spiral infill

Make hollow objects with Planar Additive Thin Wall Helical

Perform multiple finish passes on inner and outer boundaries

Use 5-axis movement to align with drafted walls

Rotary deposition:

Define simple rotary axis movement with build-up properties

Create round features along the part axis or add features to a round part

Align print head with draft angles of features

Use thin-wall option for flanges or similar features

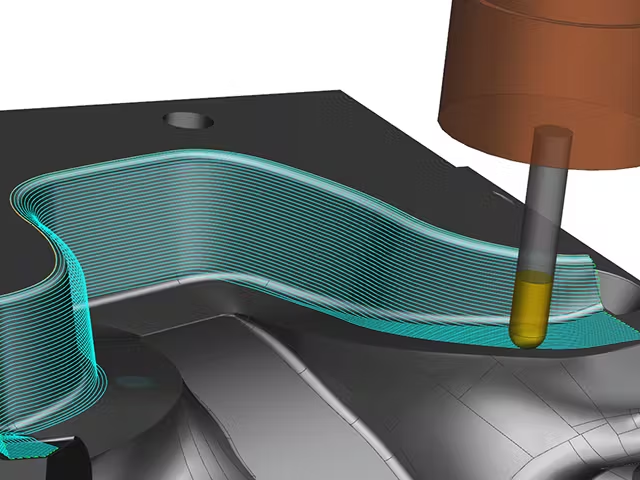

Freeform deposition:

Build-up “skins” on 3D freeform geometry

Construct thin wall features

Build features onto 3D shapes

Ensure build-up consistency

Tube deposition:

Perform a single pass build-up for tube structures

Apply efficient helical motion to deposition

Vary slice thickness based on geometry

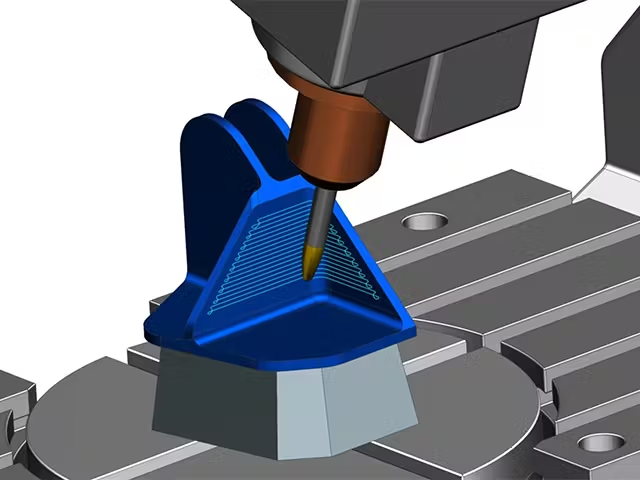

Some multi-axis and hybrid additive machines use a full 5-axis setup for material deposition. This has the advantage of creating a higher-quality surface finish with better deposition accuracy and a better net shape.

Having robust 5-axis deposition support in software is important because some 5-axis printing technologies have unique requirements. For example, wire arc deposition can result in an undesired condition where the arc jumps from the area of deposition to another area of the part if the deposition head gets too close. Adjusting the angle of the deposition head can alleviate these issues, and this is the type of robust planning for the 5-axis deposition that NX AM Multi-Axis provides.

Furthermore, having a world-class CAM system integrated into the same system as our NX additive manufacturing solutions means you can easily switch between additive and subtractive operations when using a hybrid manufacturing machine. This helps reduce the waste resulting from non-optimal manufacturing processes, like having to use multiple software solutions.

Explore NX for manufacturing products

View our professional solutions for pragmatic, industrial additive manufacturing design.

NX AM Fixed-Plane

NX AM Fixed-Plane offers build tray setup, creation of basic support geometry (block, line, and point), and a build processor framework that supports a wide range of additive manufacturing (AM) equipment.

NX AM Build Optimizer

Maximize the efficiency of additive manufacturing by optimizing the orientation of parts in the build tray. Eliminate build errors and minimize material usage and build time by automatically orienting the part optimally.

NX X Manufacturing Value Based Licensing

NX X Manufacturing add-ons are delivered exclusively using our innovative Value Based Licensing model, providing a cost-effective solution. Expand the capabilities of your NX X Manufacturing solution with powerful add-ons.Learn more about NX for manufacturing

Customer support

Siemens offers customer support for NX and all of our products..

Contact us

NX for manufacturing blog

Keep up with the latest news and highlights of NX for manufacturing software on our blog site.

.

Visit blog

NX for manufacturing community

Join the conversation or get answers to all of your NX for manufacturing software questions.

Visit community