NX X Manufacturing

Advanced

Program freeform parts with NX X Manufacturing Advanced, which builds upon the Standard product, using 3-axis milling capabilities powered by cloud technologies.

Why NX X Manufacturing Advanced?

NX X Manufacturing Advanced is a comprehensive and scalable solution that enhances the capabilities of the Standard version by introducing advanced 3- and 2.5-axis milling, turning, and on-machine probing functionalities. It leverages industry-leading integrated CAD/CAM tools to simplify the preparation and programming of complex freeform parts such as molds and dies. With its intelligent toolpath technologies, manufacturers can achieve exceptional surface finishes while reducing cutting time by up to 60%, significantly improving productivity and efficiency.

Key Features:

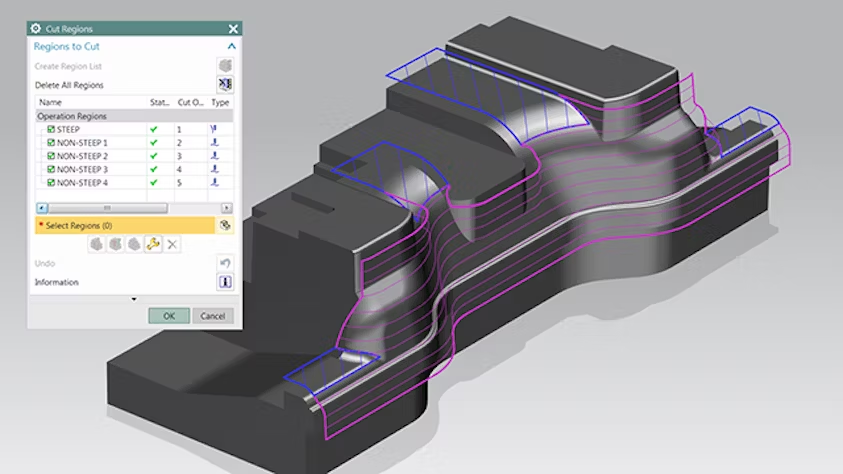

3-Axis Milling: Manufacture high-quality freeform components using advanced NC programming tools. The 3D Adaptive Roughing method reduces machining time by half, while automated rest milling supports multi-stage roughing. Cut region control ensures precise strategy management, and smooth finishing operations follow natural part geometry for superior surface quality.

Data Management: Access cloud-based CAM data management for efficient file handling, including check-in/check-out and revision control. Built-in collaboration tools like discussion threads and task assignments enhance communication between designers and manufacturers.

2.5-Axis Milling : Accelerate prismatic part programming with volume-based and feature-based machining. High-speed strategies cut machining time by up to 60%, while multiple-part programming improves throughput and consistency.

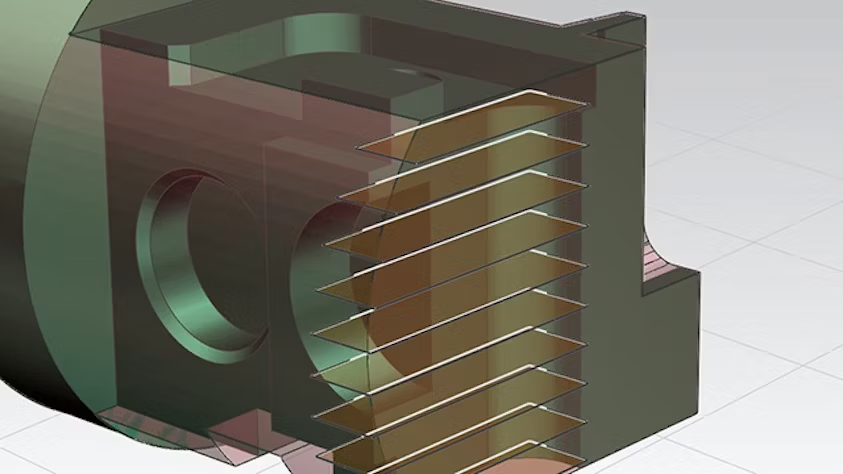

Turning : Efficiently machine cylindrical parts with single or dual spindles. Comprehensive operations include roughing, facing, boring, threading, and grooving, with precise control for inner and outer diameters.

On-Machine Probing : Generate and simulate probing paths for both milling and turning. Integrated with a digital twin of the part and machine, this feature detects process variations and optimizes machining accuracy.

Simulation, Postprocessing, and Documentation : Use integrated simulation and postprocessing tools to produce production-ready G-code. The cloud-based Post Hub offers access to over 1,000 postprocessors, while the Post Configurator and machine tool builder tools enable complete customization and associative work instructions.

Integrated CAD Tools : Utilize advanced modeling, editing, and assembly features for faster CNC programming. With built-in translators, NX CAM supports all major data formats such as IGES, DXF, STEP, STL, and JT, ensuring seamless data exchange and workflow integration.

NX X Manufacturing Advanced empowers manufacturers to handle complex machining tasks with precision, speed, and flexibility — delivering top-quality parts and measurable productivity gains.

Benefits of NX X Manufacturing:

- Program using advanced CAD/CAM tools tailored to your specific manufacturing needs

- Reduce upfront costs and streamline deployment with cloud technology

- Increase productivity with industry-leading CNC programming capabilities

- Improve collaboration among stakeholders using cloud-based solutions

- Expand the functionality of your solutions with Value Based Licensing

Customizable solution

Expand the functionality with NX X Manufacturing Value Based Licensing to configure and customize your solutions, including:

- Advanced modeling tools

- Specialized machining capabilities

- G-code-driven simulation

- Modern postprocessing solution

NX X Manufacturing Advanced capabilities

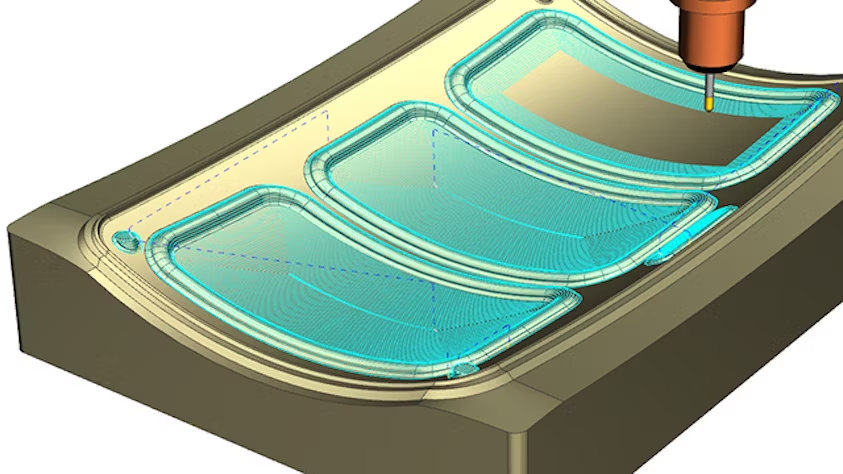

Reduce your machining time and overall production costs with 3D Adaptive Roughing, a high-performance cutting strategy designed for maximum efficiency. This advanced technique allows for deep cuts while maintaining a consistent tool load, leading to exceptionally high material removal rates. Optimized for cutting hard materials, 3D Adaptive Roughing not only shortens machine cycle times by up to 60% but also significantly extends tool life, ensuring smoother operations, lower tool costs, and enhanced productivity on the shop floor.

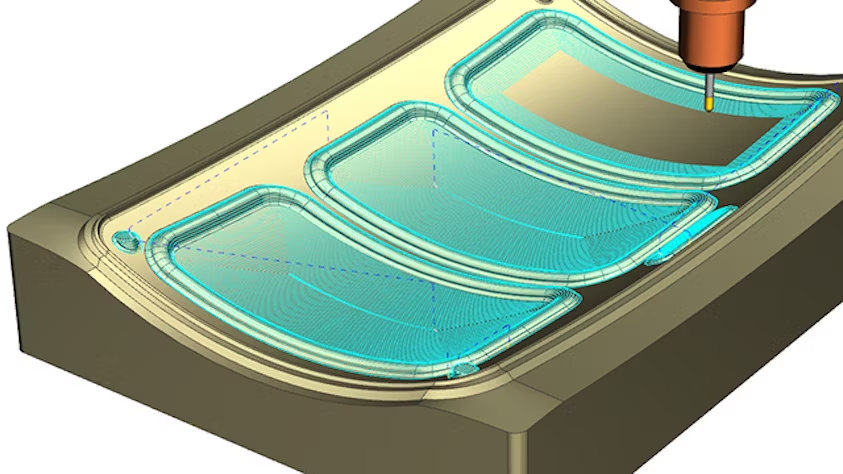

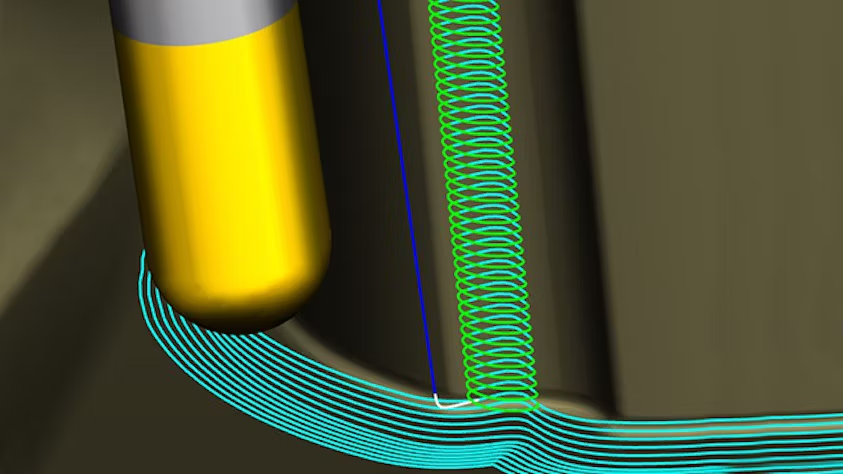

NX Advanced Finishing methods enable manufacturers to achieve exceptional surface quality and precision through smooth, optimized toolpaths.

The Helical Finishing technique gradually steps over, eliminating tool marks and ensuring a flawless surface finish — making it ideal for machining high-quality parts with steep walls. Meanwhile, the Spiral Finishing method is perfectly suited for machining shallow, symmetrical regions, maintaining consistent material removal and smooth transitions.

These advanced finishing strategies deliver a uniform stepover and eliminate sharp tool movements, resulting in improved surface finish, enhanced machining accuracy, and higher cutting speeds for greater overall efficiency.

NX offers adaptive high-speed cutting strategies designed to maximize machining efficiency. This advanced roughing technique enables deeper cuts and maintains a consistent tool load, allowing for significantly higher material removal rates.

Perfect for machining hard materials, this innovative approach can reduce machining cycle times by up to 60% while simultaneously extending tool life — delivering faster, more cost-effective, and reliable production results.

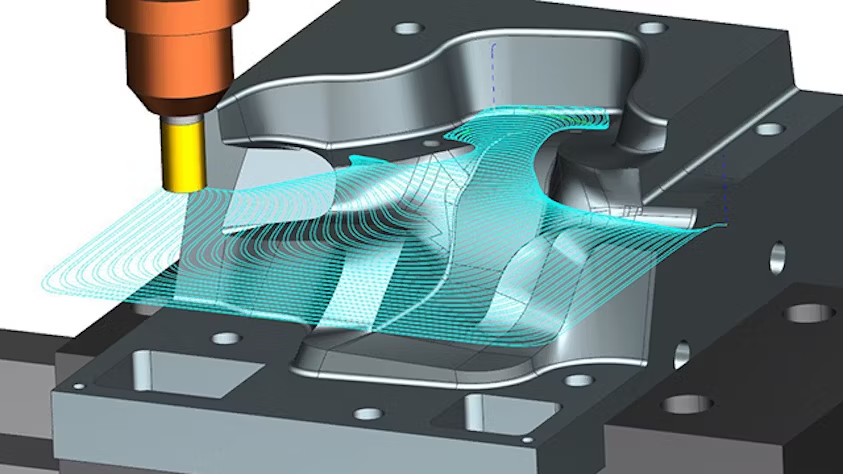

Flow Milling is an advanced automated rest milling strategy designed to efficiently remove uncut material left from previous operations. It intelligently generates optimized toolpaths using smaller tools to precisely target remaining material, ensuring complete and accurate machining.

With advanced control options, Flow Milling offers flexibility to apply the most effective cutting method for different regions of a part — including shallow and stepped areas. The arc fitting capability further enhances performance by creating smoother toolpaths, maximizing circular movements, and minimizing short linear transitions.

These optimized toolpaths deliver key benefits such as reduced machining times, improved machine tool performance, and higher surface quality, making Flow Milling an essential method for achieving efficiency and precision in modern manufacturing.

Boost productivity by up to 25% with automated edge detection on specified part geometry. This intelligent process identifies edges and applies the most suitable tools—such as chamfer, ball, or spherical cutters—to perform deburring or chamfering with precision. It also generates efficient helical deburring toolpaths for closed edges, ensuring smoother transitions and superior edge quality. Additionally, the use of 3-axis spline non-cut motions further enhances machining efficiency, minimizing tool movement time and optimizing overall production performance.

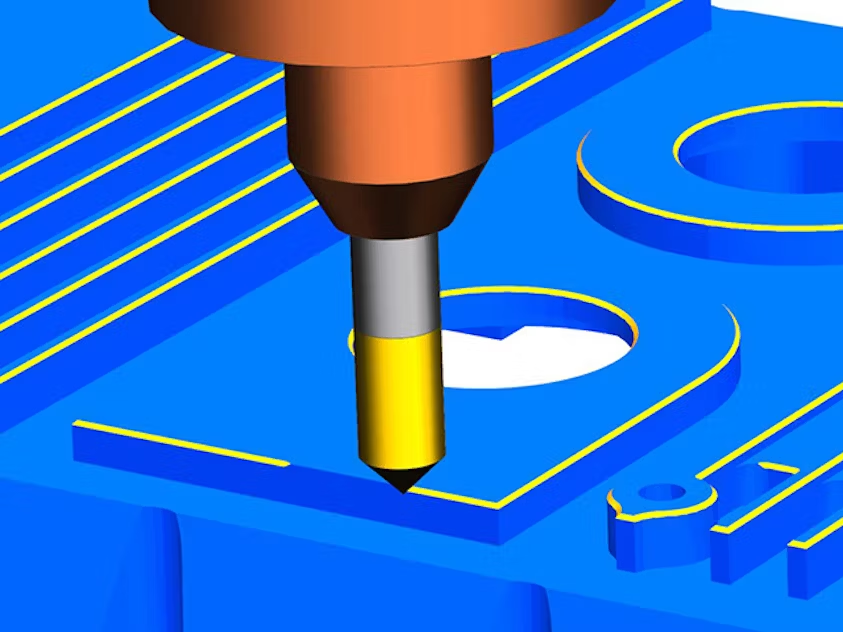

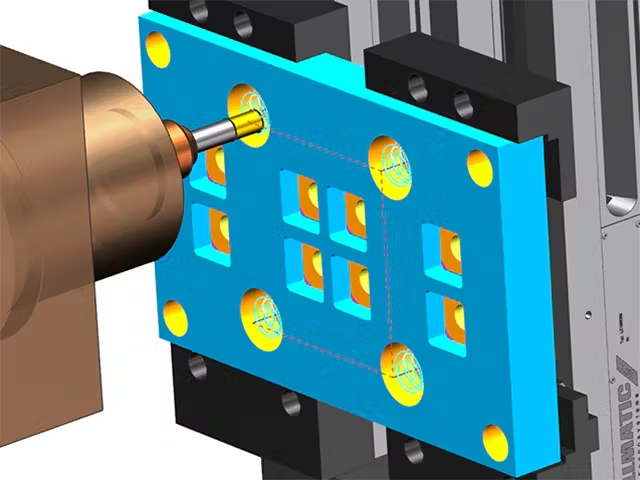

Simplify the programming of prismatic parts with an intuitive process that allows you to preview and define the sequence of machining volumes. By simply selecting 3D solid faces to define features, NX eliminates the time-consuming task of manually creating and selecting boundaries required in traditional numerical control (NC) programming.

This interactive and visual programming approach displays calculated cut levels and updates the in-process workpiece (IPW) in real time, enabling the quick creation of efficient, associative toolpaths. Thanks to full CAD/CAM integration, any design modification automatically updates machining operations, helping you respond rapidly to design changes and maintain seamless workflow continuity.

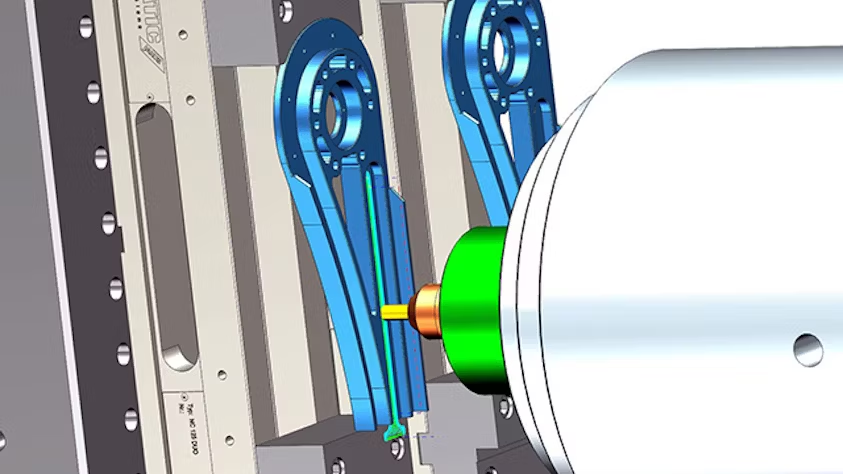

Generate and visualize probing paths to ensure precise measurements and alignment.

Create on-machine probing cycles for both milling and turning operations to enhance accuracy and efficiency.

Output NC code seamlessly using the integrated postprocessor for consistent and reliable results.

Simulate the entire process using the digital twin of the part, probe and machine tool to predict and prevent potential issues.

Detect process variations in real time to adjust machining parameters and maintain optimal performance.

Machining simulation is one of the key advantages of NX CAM, offering fully integrated simulation and verification within the NC programming environment. This allows programmers to check and validate tool paths directly, without relying on separate simulation software or transferring data between systems.

NX provides multiple levels of simulation capabilities, enabling comprehensive validation of the machining process. These include toolpath verification for quick visual checks, material removal simulation to ensure accuracy and detect collisions, and G-code-driven simulation (available as an add-on) for complete validation of the final machine code. Together, these tools help manufacturers achieve higher precision, reduce errors, and ensure safe and efficient machining operations.

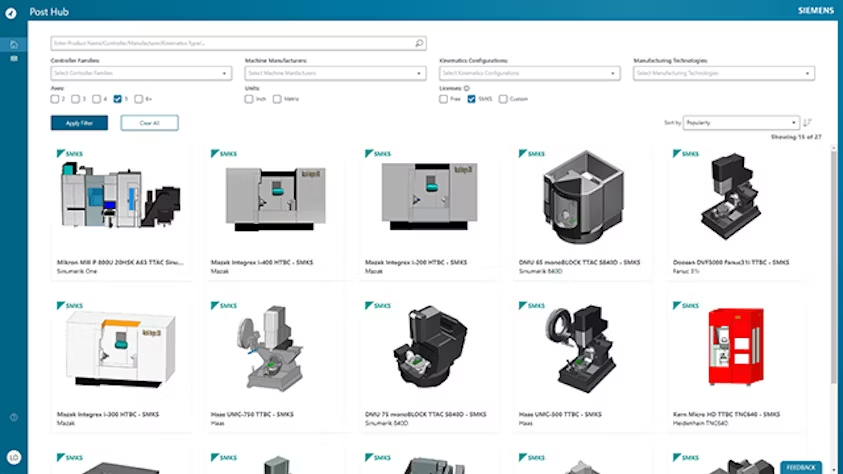

Post Hub is a modern, cloud-based postprocessing platform designed to help manufacturers generate production-ready NC programs efficiently. With access to an extensive online library of over 1,200 postprocessors and machine kits, Post Hub supports a wide range of operations including milling, turning, mill-turn, electrical discharge machining (EDM), and additive manufacturing. This ensures seamless compatibility with diverse manufacturing setups and rapid deployment of machining programs.

Additionally, Smart Machine Kit Solutions (SMKS) are available on Post Hub, representing digital twins of CNC machine tools. Each kit includes a highly accurate digital model of the machine, complete with kinematics, postprocessor, and G-code-driven simulation. This allows users to program, simulate, and output fully optimized programs for a variety of CNC machines, including Haas, DMG MORI, Okuma, and Makino. By combining advanced digital simulation with cloud accessibility, Post Hub ensures faster, more reliable, and more efficient manufacturing workflows.

NX CAM delivers industry-leading CAD capabilities for modeling, editing, and assembly, significantly accelerating the CNC programming process. With integrated translators, users can easily import and work with all major data formats, including IGES, DXF, STEP, STL, and JT, ensuring seamless data exchange and collaboration across platforms.

The software’s Synchronous Technology enables direct and intuitive editing of part models, allowing users to quickly prepare designs for NC programming. Tasks such as closing holes, filling gaps, offsetting faces, and resizing features can be done effortlessly. It also allows the creation of as-cast models or design derivatives by simply pushing and pulling existing part faces.

Using powerful assembly tools, NX CAM lets you build a precise digital twin of the complete setup — including the part, fixtures, table, and CNC machine. This helps generate optimized toolpaths that automatically avoid workholding components, ensuring safe and error-free machining operations.

Additionally, NX CAM maintains full associativity to the part model, meaning any design or setup modification automatically updates the related machining operations. This tight integration between CAD and CAM enhances efficiency, accuracy, and responsiveness throughout the entire manufacturing process.

Explore the four scalable tiers of NX X Manufacturing solutions: Essentials, Standard, Advanced and Premium

Best software for CNC programming and production

Subhashis.S, Staff Engineer, Enterprise Company

Read G2 review

Single integrated system with range of functionalities

Naveen, Sr Design Engineer, Enterprise

Read G2 review

Automated programming with high precision & efficiency

Saurabh K, Software Engineer, Enterprise Company

Read G2 review

Explore related NX X Manufacturing products

Get more details about our wide range of cloud solutions for your specific part manufacturing needs.

NX X Manufacturing Standard

Automate prismatic part programming with integrated CAD/CAM technology, featuring 2.5-axis milling, hole making, turning, and on-machine probing capabilities—all seamlessly connected to industry-leading CAD tools and powered by cloud technologies.

NX X Manufacturing Premium

Utilize 5-axis milling, rotary machining, advanced 3- and 2.5-axis milling, turning, and on-machine probing capabilities, along with other high-end functionalities. Optimize complex part machining with powerful multi-axis machining strategies.

NX X Manufacturing Value Based Licensing

NX X Manufacturing add-ons are available exclusively through our innovative Value-Based Licensing model, offering a flexible and cost-effective way to extend your capabilities. Enhance your NX X Manufacturing solution with a wide range of powerful add-ons.Teamcenter Share: cloud-based collaboration

Optimize Your Production Process with Teamcenter Share Teamcenter Share, a next-generation cloud-based collaboration solution from Siemens, enables seamless integration with NX CAM software to optimize your entire production process. It allows secure communication and information sharing with internal and external stakeholders directly in the cloud, enhancing teamwork and productivity.

By connecting design, manufacturing, and shop floor teams, Teamcenter Share facilitates a more flexible and efficient production workflow. Every NX CAM subscription includes access to Teamcenter Share, which provides secure central storage, email-based sharing, and instant collaboration with colleagues, partners, and customers.

Administrators receive an Enterprise Cloud Account (ECA), allowing them to manage access and delegate privileges to other users. In addition, all authorized Teamcenter Share users (except guest users) are granted access to the “Getting Started with Siemens Xcelerator Academy” (LAAS49000) on-demand training through the Siemens Xcelerator Academy portal, ensuring they can quickly learn and make the most of the platform’s capabilities.

Learn more about NX for manufacturing

Customer support

Siemens offers customer support for NX and all of our products..

Contact us

NX for manufacturing blog

Keep up with the latest news and highlights of NX for manufacturing software on our blog site.

.

Visit blog

NX for manufacturing community

Join the conversation or get answers to all of your NX for manufacturing software questions.

Visit community