NX X Manufacturing

Standard

Automate prismatic part programming using 2.5-axis milling, hole making, turning and on-machine probing capabilities powered by cloud technologies.

₹623,869.09

INR per quantity / per year Only ₹51,989.09 per month You’re viewing products and pricing for India Change country

Why NX X Manufacturing Standard?

NX X Manufacturing Standard offers automated prismatic part programming powered by integrated CAD and CAM tools. It supports 2.5-axis milling, hole making, turning, and on-machine probing — all within one streamlined environment. With advanced automation and seamless CAD integration, it significantly reduces programming time by up to 90%, helping manufacturers achieve faster and more efficient part production.

Key Features:

2.5-Axis Milling:Enables faster programming of prismatic parts using volume-based milling.Automates machining through feature-based technology.High-speed machining strategies reduce machining time by up to 60%.Supports multiple-part programming for greater productivity.

Data Management:Access cloud-based CAM data management with file check-in/check-out and revision control.Identify dependencies between design parts and CAM setups.Collaborate effectively using integrated discussion threads and task assignments.

Turning:Machine cylindrical parts on single or dual-spindle lathe machines.Supports roughing (face, turn, back turn, bore, undercut) and finishing (multi-pass and facing).Includes hole-making (spot, drill, peck, chip, ream, tap) and grooving/threading for inner and outer diameters.Simulation, Postprocessing & Shop

Documentation:Use toolpath animation and postprocessors to generate production-ready G-code.Access over 1,000 postprocessors from Post Hub or customize with Post Configurator.Create machine tool kinematic models and generate associative work instructions.

Integrated CAD Tools:Industry-leading CAD functions for modeling, editing, and assemblies to speed up CNC programming.Supports standard data formats: IGES, DXF, STEP, STL, JT.(Manufacturing metrics are based on internal test machining and comparison studies.)

Benefits of NX X Manufacturing

- Leverage advanced CAD/CAM tools designed to meet your unique manufacturing requirements

- Lower upfront investment and simplify deployment through cloud-based technology

- Boost productivity with industry-leading CNC programming capabilities

- Enhance collaboration among teams and stakeholders via cloud-enabled solutions

- Extend and customize functionality with Value-Based Licensing

- Fully adaptable and customizable to fit your business needs.

Customizable solution

Expand Your Capabilities with NX X Manufacturing Value-Based Licensing

- Configure and tailor your solutions with access to advanced capabilities, including:

- Comprehensive modeling and design tools

- Specialized machining functionalities

- Accurate G-code–driven simulation

- State-of-the-art postprocessing solutions

NX X Manufacturing Standard capabilities

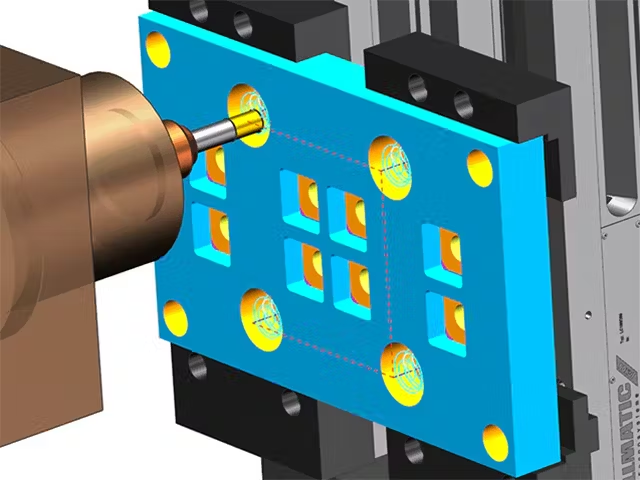

Simplify the programming of prismatic parts with an intuitive, volume-based approach. Instead of manually defining and selecting boundaries, you can simply choose 3D solid faces to specify the machining sequence. This eliminates tedious setup steps found in traditional NC programming.

The interactive programming interface provides real-time previews of calculated cut levels and the updated in-process workpiece (IPW), allowing you to quickly generate efficient and accurate toolpaths.

Because the system is fully associative, any design change automatically updates the related machining operations, enabling you to respond faster and maintain consistency through an integrated CAD/CAM workflow.

Achieve precise Automatically generate optimized machine programs directly from 3D part models using feature-based machining (FBM), cutting programming time by up to 90%. FBM intelligently recognizes and programs a wide range of machining feature types, including prismatic, turning, wire EDM, color, and attribute-based features.

NX also reads product and manufacturing information (PMI) — such as tolerances, surface finishes, and other annotations embedded in the model — to automatically determine the most suitable machining methods, ensuring precision and consistency throughout the process.

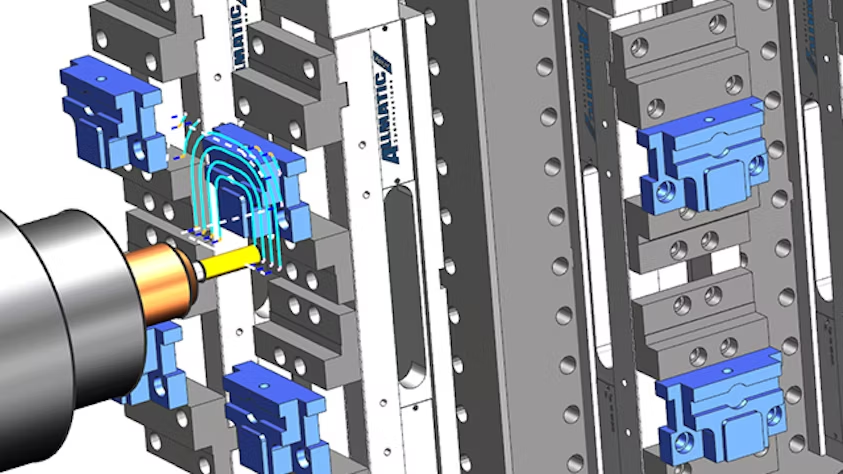

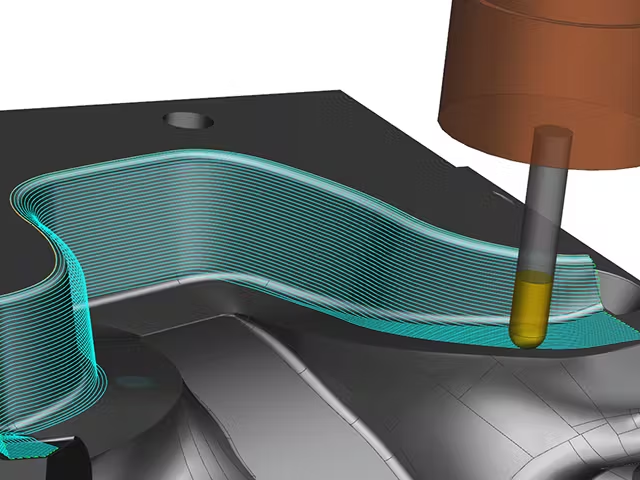

NX offers adaptive high-speed cutting strategies designed to maximize machining efficiency. This advanced roughing technique enables deeper cuts and maintains a consistent tool load, allowing for significantly higher material removal rates.

Perfect for machining hard materials, this innovative approach can reduce machining cycle times by up to 60% while simultaneously extending tool life — delivering faster, more cost-effective, and reliable production results.

Planar deburring in NX automates one of the most common machining operations—corner chamfering—reducing programming time by up to 90%.

The feature automatically recognizes both modeled and unmodeled part edges, generating optimized toolpaths to achieve the required chamfer size. Users can define a size range for holes to be skipped, providing precise control over the deburring process.

Additionally, NX intelligently tracks already chamfered corners to avoid redundant cutting, ensuring smooth, efficient 3+2 machining and minimizing tool wear.

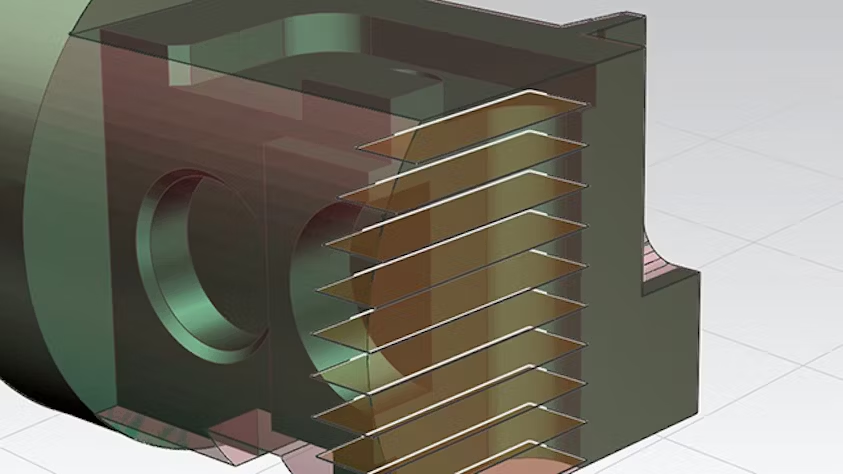

PrimeTurning™ is an advanced machining technique developed in collaboration with Sandvik Coromant, utilizing high-performance CoroTurn Prime inserts to deliver exceptional efficiency and precision.

Unlike conventional turning, the tool enters the workpiece near the chuck and removes material while moving away from it, allowing for smaller entering angles and more aggressive cutting parameters. The same CoroTurn Prime inserts can also be used in the traditional direction—from the part end toward the chuck—for added flexibility.

PrimeTurning supports dual roughing operations and continuous B-axis machining, providing versatility across different setups. In many applications, this method can increase productivity by over 50% and double tool life, setting a new benchmark in high-performance turning.

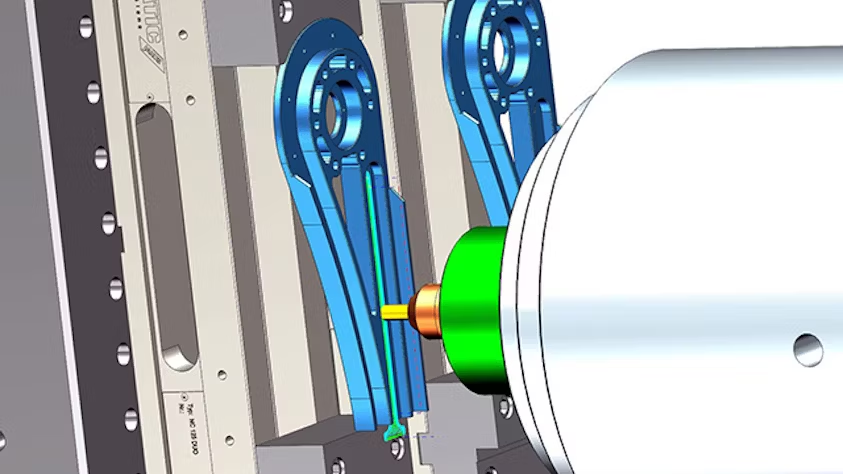

Multiple-part programming offers a powerful and efficient approach to multipart machining, streamlining the setup of complex tombstone and fixture configurations. This feature enables the rapid distribution of toolpaths across multiple components, regardless of their position or orientation.

With this advanced method, complete machining sequences and toolpaths created for one workpiece can be instantly replicated across others, ensuring consistency and reducing manual effort. As a result, you can prepare full production jobs in the same amount of time it would take to program a single part, dramatically improving productivity and workflow efficiency.

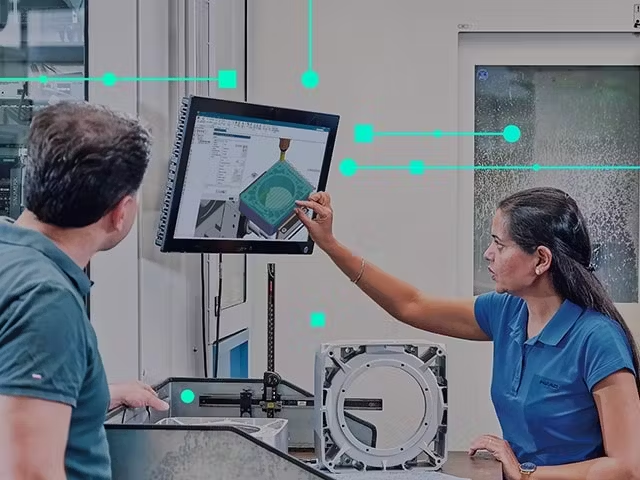

Machining simulation is one of the core advantages of NX CAM, offering integrated simulation and verification directly within the NC programming environment. This built-in capability allows programmers to validate toolpaths in real time—eliminating the need for separate simulation software or data transfers between different systems.

NX provides multiple levels of machining simulation to suit varying production needs, including:

Toolpath verification – visually review and validate programmed tool movements.

Material removal simulation – simulate the actual machining process to detect potential collisions or inefficiencies.

G-code–driven simulation (available as an add-on) – use the same G-code that runs on the machine to ensure accurate, real-world verification of tool motion.

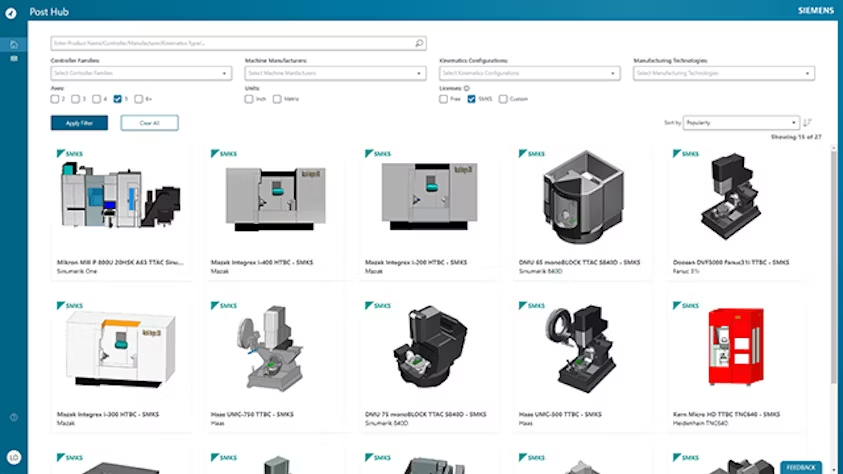

Post Hub is a modern, cloud-based postprocessing platform that enables the creation of production-ready NC programs with ease and efficiency. With an extensive online library containing over 1,200 postprocessors and machine kits, users can quickly generate programs for a variety of operations — including milling, turning, mill-turn, EDM, and additive manufacturing.

Additionally, Smart Machine Kit Solutions (SMKS) are available within Post Hub, representing the digital twins of CNC machine tools. Each kit includes a highly accurate digital model complete with machine kinematics, postprocessor, and G-code-driven simulation. SMKS empowers manufacturers to program, simulate, and output optimized programs for leading CNC machines such as Haas, DMG MORI, Okuma, and Makino, ensuring greater precision and efficiency across machining operations.

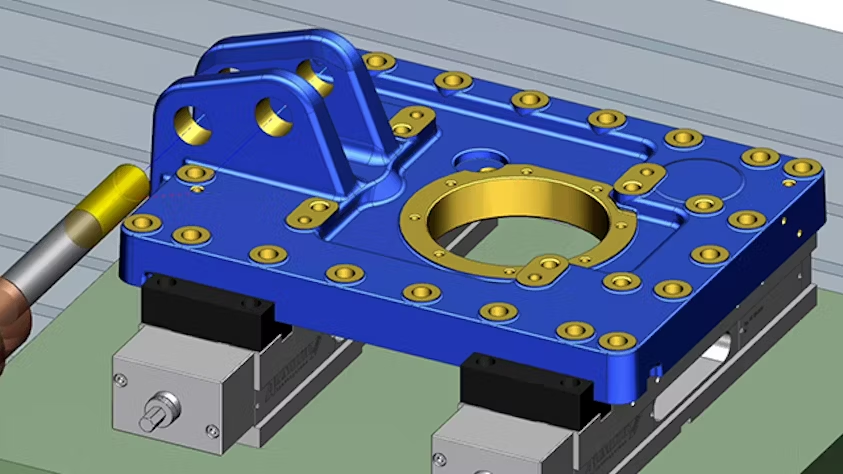

NX CAM offers industry-leading CAD modeling, editing, and assembly capabilities that significantly accelerate CNC programming. Its integrated translators support all major data formats — including IGES, DXF, STEP, STL, and JT — ensuring seamless interoperability across design and manufacturing workflows.

With synchronous technology, programmers can directly edit part models to prepare them for NC programming tasks such as closing holes and gaps, offsetting faces, and resizing features. This flexibility allows users to quickly create as-cast models or other design derivatives by interactively pushing and pulling existing faces.

The advanced assembly tools enable the creation of a fully accurate digital replica of the machining setup — including the part, fixtures, table, and CNC machine. This comprehensive setup ensures optimized toolpaths that automatically avoid workholding components, resulting in safer and more reliable machining.

Additionally, full associativity between the machining operations and the part model ensures that any changes in the design or setup automatically update the NC program, maintaining accuracy and consistency throughout the entire process.

Explore the four scalable tiers of NX X Manufacturing solutions: Essentials, Standard, Advanced and Premium

Precision planning and shop floor operations

Tarun K., Senior Software Engineer, Enterprise Company

Read G2 review

Best CAM package in the market

Joel G., R&D, Mid-Market Company

Read G2 review

NX CAM empowers our manufacturing process

Luis Edison G., Small-Business Customer

Read G2 review

Explore related NX X Manufacturing products

Get more details about our wide range of cloud solutions for your specific part manufacturing needs.

NX X Manufacturing Advanced

Use advanced 3- and 2.5-axis milling, turning, on-machine probing capabilities among other advanced functionalities. Leverage integrated CAD/CAM tools streamline the preparation & programming of the most demanding freeform parts.

NX X Manufacturing Premium

Utilize 5-axis milling, rotary machining, advanced 3- and 2.5-axis milling, turning, and on-machine probing capabilities, along with other high-end functionalities. Optimize complex part machining with powerful multi-axis machining strategies.

NX X Manufacturing Value Based Licensing

NX X Manufacturing add-ons are available exclusively through our innovative Value-Based Licensing model, offering a flexible and cost-effective way to extend your capabilities. Enhance your NX X Manufacturing solution with a wide range of powerful add-ons.Teamcenter Share: cloud-based collaboration

Optimize your entire production process with Teamcenter Share, a next-generation, cloud-based collaboration solution from Siemens, which seamlessly connects to NX CAM software. Securely communicate and share information with internal and external stakeholders in the cloud.

Connect design, manufacturing and shop floor teams to run a more flexible and efficient production.

Your subscription also includes access to Teamcenter Share. With capabilities including secure, central storage and e-mail address-based sharing, Teamcenter Share allows you to instantly, securely and easily collaborate with colleagues, partners and customers. An Enterprise Cloud Account (ECA) will be provided to you for administrators to gain access to Teamcenter Share and delegate additional privileges.

Except guest users, all Authorized Users of Teamcenter Share cloud services will receive access to “Getting Started with Siemens Xcelerator Academy” (LAAS49000) on-demand training on the Siemens Xcelerator Academy portal.

Learn more about NX for manufacturing

Customer support

Siemens offers customer support for NX and all of our products..

Contact us

NX for manufacturing blog

Keep up with the latest news and highlights of NX for manufacturing software on our blog site.

.

Visit blog

NX for manufacturing community

Join the conversation or get answers to all of your NX for manufacturing software questions.

Visit community